The packaging industry is adopting intelligent and sustainable solutions to make product packaging more consumer, brand, and environmentally friendly. The main packaging industry trends to achieve intelligent packaging are packaging Internet, active packaging and nanotechnology. Meanwhile, visionary enterprises have accelerated innovation in biodegradable, recyclable, and edible packaging. In addition, the deployment of 3D printing and robot packaging has simplified the packaging process and reduced costs for consumer goods companies.

1. Packaging Internet

The packaging Internet has brought technological disruption to traditional packaging, enabling consumers to better connect with brands.

Intelligent packaging utilizes technologies such as QR codes, smart tags, RFID, and near-field communication (NFC) chips. These cutting-edge solutions provide value-added advantages such as security, authentication, and connectivity, making product packaging a data carrier and digital tool.

AR Packaging provides customers with better opportunities to interact with customers by introducing a series of product content, discount codes, and video tutorials. In addition, IoT devices allow brands to integrate diagnostic and indication functions in their packaging, providing customers with real-time product status.

2. Biodegradable packaging

Plastic has been the most commonly used packaging material since the early 20th century. However, its slow decomposition speed can lead to a wide range of environmental problems. As consumers become increasingly aware of the negative consequences of disposable plastic packaging, they need environmentally friendly alternatives. Biodegradable packaging and films are becoming increasingly popular and suitable alternatives to traditional plastic packaging.

For example, starch, cellulose, PLA, polyhydroxybutyrate (PHB), polyhydroxyalkanoate (PHA), and other biopolymers. In addition, plant-based packaging for sugarcane, coconut, hemp, and corn starch has also replaced plastic packaging. These innovations are cost-effective for businesses and can reduce the environmental impact of the packaging industry.

3. Digital printing

The packaging printing process faces many challenges, including accuracy, low color quality, and high labor costs. This provides an opportunity for innovation in digital printing technology, making it one of the top trends in the packaging industry. Unlike traditional offset or flexographic printing techniques, it does not require the use of separate printing plates for different printed materials. All content is printed once through digital printing, reducing workload.

The impact of modern digital printing on the environment is limited as it eliminates the need for prepress procedures or additional labels, reduces waste and inventory requirements. Digital printing has shorter turnaround time and greater flexibility, allowing for customized packaging for brands to meet different consumer groups. Direct thermal printing is another printing technique that uses thermal imaging to print labels and flexible packaging without the need for ink.

4. Packaging automation

The main challenges related to packaging are productivity, accuracy, and quality control. The automation of packaging processes such as demolding, filling, packaging, and palletizing is a major trend in the packaging industry. The automation of packaging using robotic arms and fixtures not only eliminates human errors, but also ensures the safe handling of exquisite products.

Finally, the startup also developed an artificial intelligence driven visual system that can take photos of finished products to analyze packaging quality. These visual assisted robots can automate processes such as product classification, quality control, and inspection to improve overall efficiency.

5. Active packaging

According to the Food and Agriculture Organization of the United Nations (FAO), one-third of the consumer food produced globally is wasted. Food waste is a huge challenge that needs to be addressed, as businesses often suffer huge losses as a result. Active packaging can extend the shelf life of products and is a trend in the continuous development of the packaging industry, which has been applied in the food, beverage, and pharmaceutical industries.

For example, modified atmosphere packaging uses oxygen or ethylene absorbents and humidity regulators to keep food fresh. Another example of active packaging is the release of antibacterial agents to prevent bacterial growth in the product.

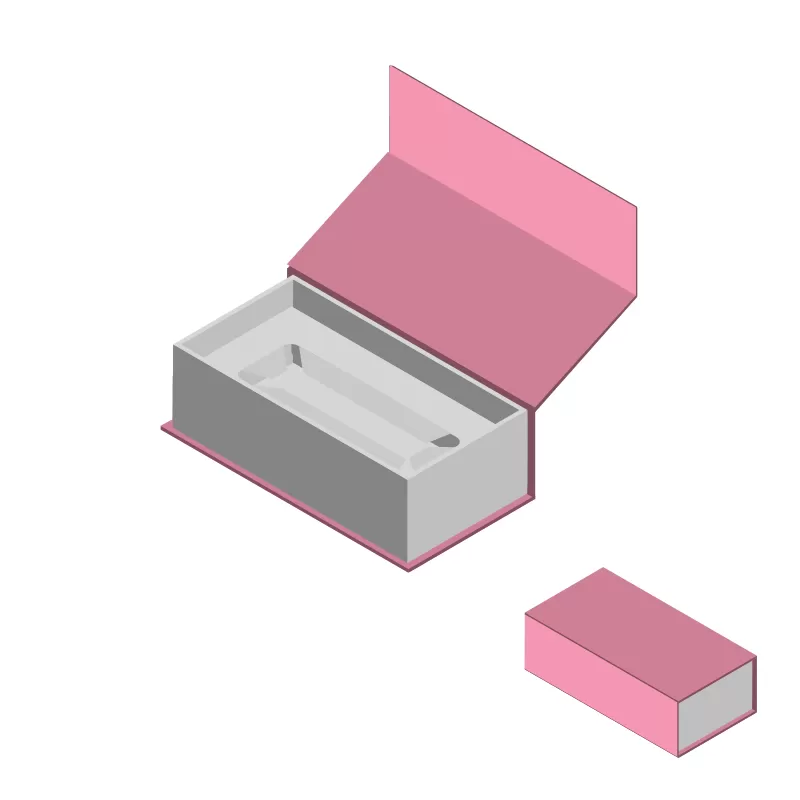

6. Customized packaging

The appearance of a product plays an important role in attracting consumers to use it. Therefore, packaging as a marketing tool for enterprises is as important as the product itself. The challenge faced by brands and custom box manufacturers is how to make packaging eye-catching to promote sales. Making the unboxing experience more personalized and unique is the key to creating a lasting impact so that customers can purchase the brand again. A good example is Coca Cola's popular "Share Cola" event, which has a name printed on the packaging to give it a personal style.

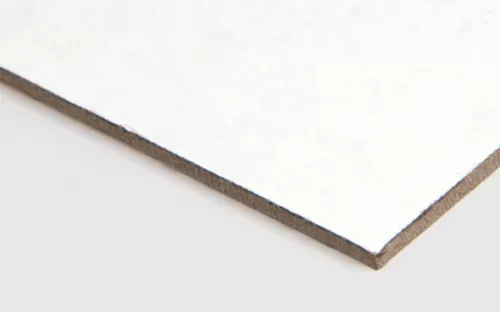

7. Recyclable packaging

With the national ban on the use of disposable plastics, companies are now seeking alternative materials for product packaging to comply with regulations. The use of recyclable materials is such a packaging solution that enables businesses to integrate circular packaging practices. For example, post consumer resin (PCR) is a recyclable packaging material extracted from post consumer waste. In addition, startups also develop single material packaging that is easy to recycle, rather than multi-layer packaging.

8. Edible packaging

Packaging follows a usage disposal model, thus generating a significant amount of solid waste, which ultimately either enters landfills or water bodies. That's why in the past decade, businesses and consumers have been shifting towards sustainable packaging. The challenge faced by enterprises is to choose packaging that can meet this basic function while reducing or eliminating solid waste. Edible packaging is a revolutionary trend in the packaging industry that addresses these challenges and achieves a closed loop in packaging.

A good example is packaging made from milk protein, used as a casein film around food. Compared to plastic, these films are more effective in keeping food fresh. In addition, startups that produce edible spoons, straws, or other tableware provide plastic substitutes for chain restaurants, cafes, or ice cream shops.

9. 3D printing

3D printing is a constantly evolving trend in the packaging industry, allowing companies to build different prototypes and innovate their packaging lines in almost real-time. Brands often try packaging design, but this type of design is costly, time-consuming, and can result in waste. 3D printing technology can alleviate these issues and promote personalized packaging, with zero contribution to plastic waste.

This technology provides engineers and designers with greater design freedom, enabling them to produce high-quality products.

Manufacturers also use additive manufacturing technology to manufacture prototypes of packaging machinery parts, for example, by printing robotic arms for specific packaging lines.

10. Nanotechnology

Nanotechnology has been applied at all stages of the packaging supply chain, from packaging materials to product safety, certification, and tracking. The use of nanoparticles mixed with polymer chains can enhance the barrier performance and tensile strength of packaging. It can also assist brands and packaging companies in tracking and anti-counterfeiting.

In addition, nanotechnology has had a huge impact on the food packaging industry by addressing the increasingly concerned food safety issues. Applying nano coatings on the surface of packaging can protect it from the effects of dirt, dust, and stains. Finally, several types of nanosensors can be used to monitor the freshness of food and detect any chemical changes.

Our packaging experts design and engineer innovative structures tailored to your product and branding.Explore design & engineering

Our packaging experts design and engineer innovative structures tailored to your product and branding.Explore design & engineering Our packaging design specialists create exceptional custom artwork that showcase and bring your branding to the next level.Explore design & engineering

Our packaging design specialists create exceptional custom artwork that showcase and bring your branding to the next level.Explore design & engineering Create physical samples and 3D interactive prototypes final product packaging before making a final decision.Explore design & engineering

Create physical samples and 3D interactive prototypes final product packaging before making a final decision.Explore design & engineering