For those not immersed in packaging daily, distinguishing between the various types used in a business can be challenging. However, for business owners, logistics professionals, or those responsible for ordering packaging, understanding the differences between primary, secondary, and tertiary packaging is essential. This knowledge enables cost reduction, enhances packaging performance, and maximizes logistics efficiency. By grasping the roles of each packaging type, businesses can optimize their supply chain, improve product presentation, and align with customer expectations, ultimately adding value to their operations.

What is Primary Packaging?

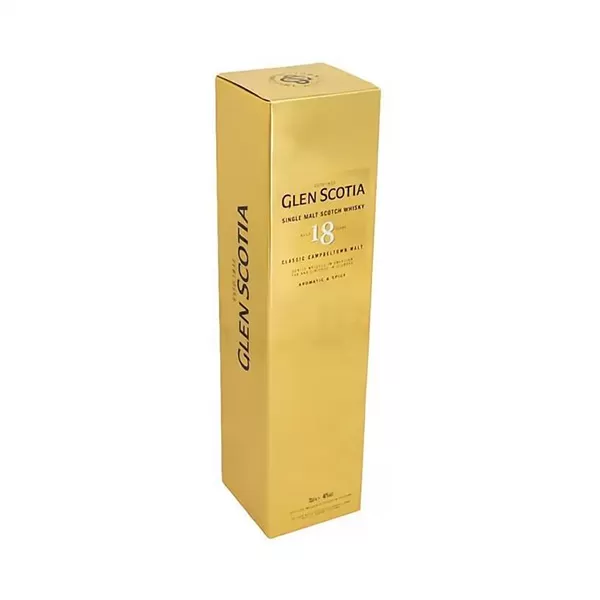

Primary packaging directly encases the consumable or usable product being sold, often referred to as sales or consumption packaging. Its primary role is to maintain the product's condition from the moment it is packed until it is removed by the customer. This packaging serves multiple purposes: it identifies the product, communicates usage instructions, expiry dates, and shelf life, and ensures the product remains secure with minimal material use. In some cases, businesses may employ multiple forms of primary packaging. For instance, a company like Baomi might package a product in a small glass container as the initial primary packaging, then place it in a retail box, which could also be considered primary packaging, depending on the business model. For e-commerce, these retail boxes may be further enclosed in a mailer box, blending the roles of primary and secondary packaging to meet specific distribution needs.

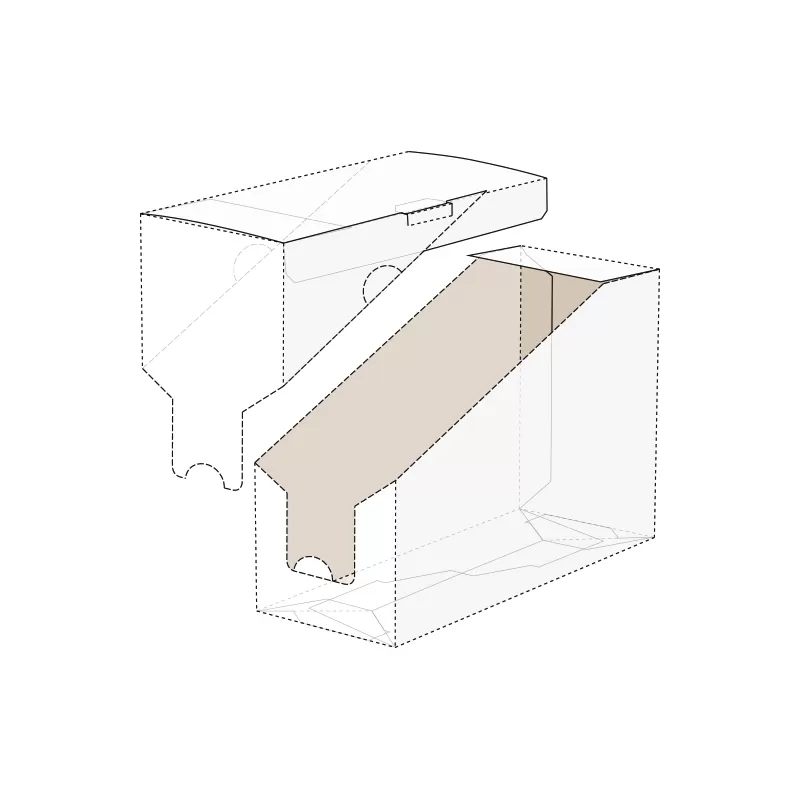

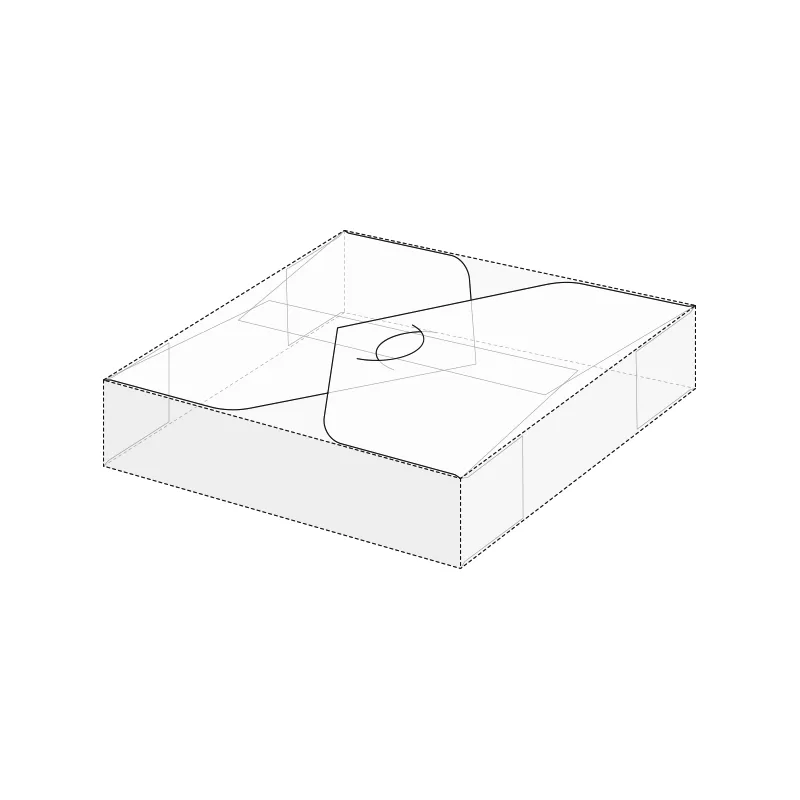

What is Secondary Packaging?

Secondary packaging, sometimes called grouped packaging, consolidates multiple units of primary-packaged products to facilitate handling and distribution. It is commonly used to leverage economies of scale, such as grouping individual product boxes into a larger container for efficient storage and transport. For example, several product units are sealed in their primary packaging and then placed in a larger cardboard box, which serves as the secondary packaging. This packaging type is designed to simplify stacking in warehouses and at points of sale, ensure safe transport over varying distances, and clearly indicate the contents. For e-commerce brands, secondary packaging often takes the form of mailing boxes or bags, balancing security and aesthetics to protect products during last-mile delivery while contributing to the unboxing experience.

What is Tertiary Packaging?

Tertiary packaging scales up the function of secondary packaging by enabling the handling and movement of multiple secondary packages at once. It focuses on stability, space efficiency, and environmental protection while supporting large-scale logistics. Tertiary packaging is designed to work seamlessly with machinery like pallet jacks and forklifts, ensuring goods can be transported and stored effectively. Common forms include wooden or plastic pallets and shipping containers, which streamline the movement of goods through the supply chain while safeguarding them from external conditions.

Why It's Important to Know the Difference

Understanding the distinctions between primary, secondary, and tertiary packaging is crucial for selecting the appropriate solutions for your business. Each type serves a specific purpose: primary packaging ensures product quality and brand communication, secondary packaging provides protection during transit, and tertiary packaging optimizes large-scale logistics to reduce costs. A mismatch, such as using a glass bottle for a shirt or inadequate secondary packaging for delicate items, can lead to inefficiencies or damage. Consistent visual branding across all packaging types reinforces the brand's values and priorities, creating a cohesive customer experience and enhancing trust in the product.

Optimising the Types of Packaging Used

Inefficient packaging can lead to significant financial and environmental costs, with studies indicating that a notable percentage of shipping containers are underutilized. By designing primary, secondary, and tertiary packaging tailored to specific needs and aligned with global standardization practices, businesses can minimize wasted space. This approach reduces costs and supports sustainable packaging strategies, particularly for small to medium-sized e-commerce businesses. Working with a packaging engineer can further optimize the supply chain, ensuring efficient use of space from production to distribution.

Standardise Your Packaging Types

Adopting globally standardized packaging measurements enhances efficiency across the supply chain, from production to storage and distribution. Standardized packaging minimizes wasted space, leading to cost savings and improved sustainability. By customizing packaging with secure, eco-friendly materials, businesses can achieve both functional and aesthetic goals. This approach also allows for complete control over visual design, ensuring the packaging aligns with brand identity while meeting logistical demands.

Factors that Determine Packaging Choice

Several factors influence the choice of packaging, including storage, handling processes, and cost considerations, which can lead to both direct and indirect savings. The point of sale or receiving point is a key determinant: retail brands require visually appealing primary and secondary packaging to stand out on store shelves, conveying essential information like usage instructions and legal details. In contrast, e-commerce brands prioritize security during courier delivery, with secondary packaging doubling as a key component of the unboxing experience. Product characteristics—such as whether the item is solid, liquid, or gas, its weight, perishability, or replacement cost—shape the design of primary and secondary packaging. Sustainability is also critical, as consumer awareness and regulations, such as bans on single-use plastics, push brands toward recyclable and reusable materials. Finally, storage and fulfillment processes require packaging that withstands stacking, long-term storage, and transport by hand or machinery, ensuring products remain protected throughout the supply chain.

Conclusion

Packaging such as the cardboard wine tube is an unavoidable business expense, but strategic implementation of primary, secondary, and tertiary packaging can significantly reduce both direct and indirect costs. By selecting the right packaging types and partnering with an experienced supplier, businesses can optimize their supply chain, enhance brand presentation, and meet customer expectations. Thoughtful packaging design not only protects products but also communicates brand values, making it a powerful tool for efficiency and customer engagement.

Our packaging experts design and engineer innovative structures tailored to your product and branding.Explore design & engineering

Our packaging experts design and engineer innovative structures tailored to your product and branding.Explore design & engineering Our packaging design specialists create exceptional custom artwork that showcase and bring your branding to the next level.Explore design & engineering

Our packaging design specialists create exceptional custom artwork that showcase and bring your branding to the next level.Explore design & engineering Create physical samples and 3D interactive prototypes final product packaging before making a final decision.Explore design & engineering

Create physical samples and 3D interactive prototypes final product packaging before making a final decision.Explore design & engineering