In the past, businesses relied on plain, cost-effective cardboard boxes for shipping, but today's customers are drawn to a package's appearance before they even open it. The way a product is packaged speaks volumes about a company, especially for first-time buyers who form their initial impressions based on the exterior. Custom boxes address this need by offering tailored packaging solutions that captivate customers with striking visuals, ensure product safety, complement marketing efforts, and foster brand loyalty. These boxes are designed to meet specific company requirements, allowing customization of shapes, sizes, materials, colors, and styles, often dictated by the product itself. This guide explores the world of custom boxes and their multifaceted benefits.

How Are Custom Boxes Made?

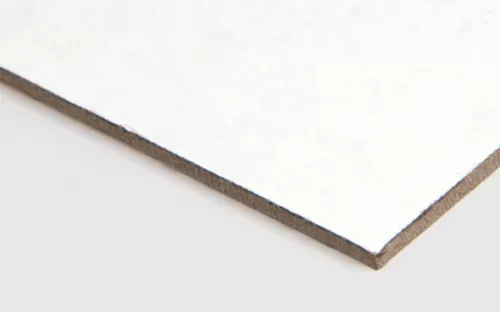

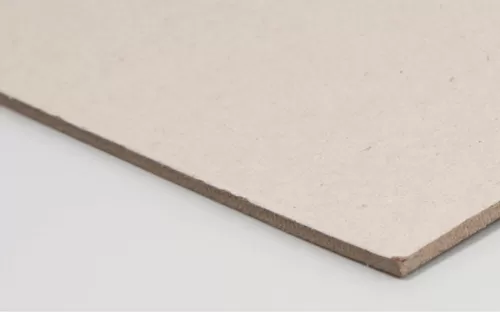

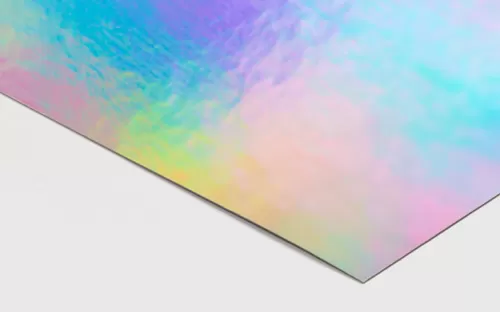

Custom boxes are crafted from various materials, with two primary options standing out. Paperboard SBS (solid bleached sulfate), a virgin fiber-grade whiteboard, is available in coated or uncoated forms and is lightweight and flat, making it ideal for printing, cutting, folding, embossing, or hot foil stamping. This material suits high-end packaging needs, such as pharmaceuticals and retail products. Alternatively, corrugated board, consisting of paperboard laminated with fluted paper in the middle, provides cushioning to protect fragile items. Available in single-wall or double-wall constructions, its sturdiness depends on the product's fragility. The manufacturing process begins once a design is provided, tailored to reflect the brand's vision and appeal to its audience.

Design and Graphics

The design phase is critical, as it shapes how customers perceive the brand. Businesses can use tools like Baomi's custom design configurator to create designs with specific colors, sizes, and graphic elements. Designers advise using bold, thicker fonts to ensure legibility, avoiding subtle details like serif fonts that may not translate well during printing. This careful attention to design ensures the packaging communicates the brand's identity clearly and effectively, setting the stage for a memorable customer experience.

Printing

Printing brings custom box designs to life, with several techniques available to suit different needs. Flexographic printing, a common method for corrugated boxes, uses a flexible plate on a rotating cylinder to print edge-to-edge designs, flood coatings, or text-based artwork, ideal for simple line art with one or two colors. However, it struggles with complex, multicolored graphics due to the cost of multiple plates and limitations like dot gain, which affects tonal range. Lithographic printing, or litho lamination, involves mounting high-resolution offset prints onto corrugated board, offering flexibility for detailed images and colors but at a higher cost, making it suitable for large-scale projects. Digital printing, a faster alternative, bypasses traditional steps like creating films or plates, applying prints directly to the board. It excels for short to medium runs but lacks the cost efficiency of analog methods for larger volumes.

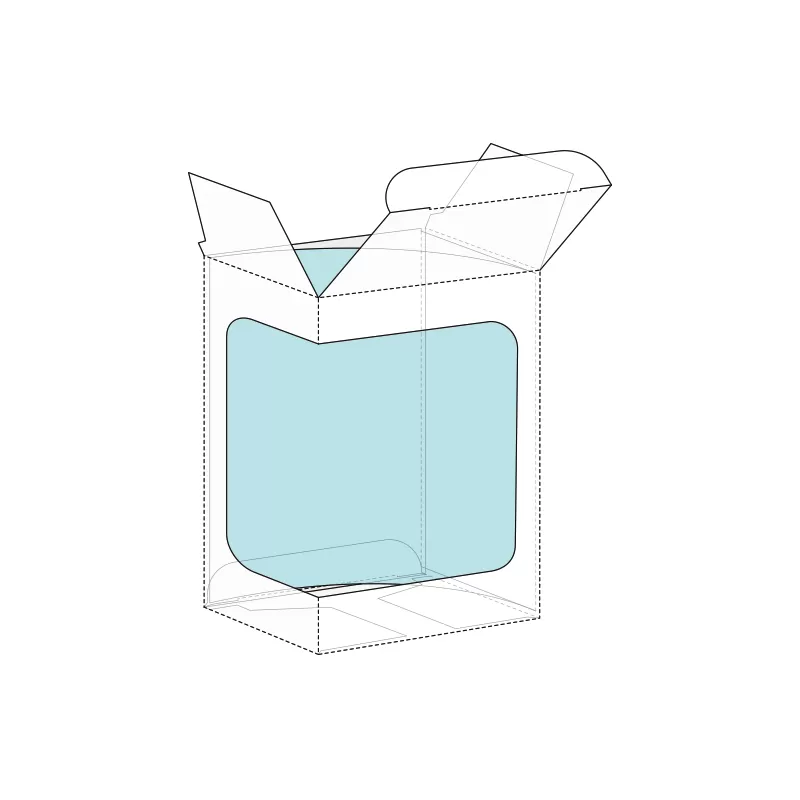

Types of Custom Boxes

Custom boxes come in various forms tailored to specific business needs. Mailer boxes, made from corrugated cardboard like E flute or B flute, feature interlocking tabs and dust flaps for easy assembly without tape or glue, offering sturdiness through double sidewalls, perfect for gift, retail, or subscription box packaging. Shipping boxes, or regular slotted cartons, use B or C flute corrugated cardboard for larger, heavier items like food, electronics, or fabrics, designed for stackable warehouse storage but requiring tape for assembly. Product boxes, or folding cartons, are lightweight paperboard options printed with art, cut, folded, and glued for retail shelves, ideal for beauty products, alcohol, or luxury goods, and delivered unassembled for customer filling. Two-piece rigid setup boxes, with a sturdy base and lid, cater to high-end products like phones or jewelry, offering endless design possibilities. Baomi's Econoflex shipping boxes, launched as a modern, eco-friendly option, are biodegradable, made from recycled materials, and cost-effective for both small and large orders due to their efficient printing technology.

Benefits of Custom Boxes

Custom boxes offer numerous advantages that elevate a brand's presence and customer experience. Unlike plain kraft boxes, custom packaging showcases logos, messages, and artwork, helping brands stand out in a crowded market. They create a memorable unboxing experience, delighting customers with vibrant colors and dynamic designs, encouraging them to share their excitement with others, amplifying brand reach. Custom boxes also ensure product safety by providing the right fit and cushioning, preventing damage from movement or poor-quality materials. Environmentally, they are made from biodegradable, recyclable materials like paperboard, reducing waste and conserving resources. By protecting products effectively, custom boxes save businesses from the costs of replacing damaged goods, with options for additional cushioning paper to enhance safety and presentation.

How Much Does a Custom Box Cost, and What Impacts Pricing?

Custom boxes are pricier than standard options, with costs varying based on box type, material, dimensions, and design complexity. Using more material or colors increases expenses, as does the choice of printing technique, though pricing largely depends on order quantity. Most custom boxes are shipped flat, requiring customer assembly, which may necessitate additional help for large orders. This flexibility in design and production allows businesses to balance cost with impact, tailoring solutions to their budget and needs.

FAQs about Custom Boxes

Custom packaging is a worthwhile investment, despite the temptation to opt for cheaper alternatives. Inadequate packaging risks product damage due to improper sizing or lack of cushioning, leading to costly replacements. Custom boxes ensure product security while enhancing the shopping experience, fostering customer loyalty and repeat purchases, ultimately boosting sales. Environmentally, they are sustainable, using biodegradable, recyclable paperboard, with around 68 percent of such materials recycled annually in the United States, according to the Environmental Protection Agency. Their precise sizing minimizes material waste, conserving resources like trees. For ordering, Baomi provides a comprehensive solution, offering mailers, shipping, and product boxes through an advanced online design tool with live previews and real-time quotes, supported by expert technicians to help craft standout designs.

Our packaging experts design and engineer innovative structures tailored to your product and branding.Explore design & engineering

Our packaging experts design and engineer innovative structures tailored to your product and branding.Explore design & engineering Our packaging design specialists create exceptional custom artwork that showcase and bring your branding to the next level.Explore design & engineering

Our packaging design specialists create exceptional custom artwork that showcase and bring your branding to the next level.Explore design & engineering Create physical samples and 3D interactive prototypes final product packaging before making a final decision.Explore design & engineering

Create physical samples and 3D interactive prototypes final product packaging before making a final decision.Explore design & engineering