When it comes to custom packaging solutions like custom luxury gift boxes, cosmetic boxes wholesale, or custom apparel boxes, the choice of printing method plays a crucial role in defining the product's aesthetic appeal and functionality. The two predominant printing techniques in the packaging industry are offset printing and silkscreen printing. Each method offers unique benefits and challenges, making it essential to understand their processes, outputs, and suitability for various applications. This comprehensive guide will explore the core differences and advantages of offset and silkscreen printing, ultimately aiding you in making an informed decision for your packaging needs.

Process Overviews

The process of offset and silkscreen printing defines much of how each method applies inks and manages designs on packaging, such as custom jewelry boxes wholesale or custom candle box solutions.

| Printing Technique | Process Outline |

|---|

| Offset Printing | Uses etched metal plates to transfer images onto rubber blankets, which are then rolled onto the custom rigid box packaging or any other substrate. |

| Silkscreen Printing | Applies ink directly onto the surface of candle packaging boxes wholesale using a mesh screen with specific areas blocked off. |

Contrastingly, offset printing is ideal for high-volume runs where consistency is key, seen often in custom bakery packaging. Silkscreen, however, allows for tactile ink layering, which can add a unique touch to custom gift boxes with logo.

Quality Outputs

The quality output from these techniques varies considerably, reflecting different levels of detail and durability needed for products like waterproof box for electronics or personalized donut boxes.

| Characteristic | Offset Printing | Silkscreen Printing |

|---|

| Detail Precision | Highly detailed images and subtle color gradients, suitable for custom magnetic closure boxes. | Bold colors and textures; less precision in gradients, perfect for pillow box packaging. |

| Durability | Long-lasting prints that resist wear; ideal for luxury jewelry boxes wholesale. | Thicker ink layers add durability, used in soap boxes wholesale. |

Offset printing is often selected for high-resolution images, ensuring crisp, clear visuals, which is why it's frequent in monogrammed tea box productions. Conversely, silkscreen printing excels with vivid, opaque colors, adding a tactile component not achievable in offset, critical for specialty custom wine box designs.

Cost for Small Runs

Economic factors significantly influence whether offset or silkscreen printing is the more viable option, especially for small runs like limited edition personalized shoe box or bespoke custom chocolate box projects.

| Cost Advantage | Offset Printing | Silkscreen Printing |

|---|

| Setup Cost | Higher due to the creation of plates; not ideal for short runs. | Lower setup costs; more suitable for limited runs. |

| Per Unit Cost | Decreases significantly with volume; economically viable for large bulk orders. | Typically remains consistent, making it feasible for niche custom soap boxes wholesale. |

The initial investment for offset printing is higher, often leading companies with high-volume requirements like beer shipping boxes to prefer this method. Silkscreen, with its lower initial costs, is attractive for short, custom runs, which is lucrative for prototype custom donut boxes or custom printed soap boxes.

Speed and Efficiency

Time is a critical factor in production line settings, with speed and efficiency directly affecting delivery timelines for custom garment boxes or 6 pack beer carrier orders.

| Factor | Offset Printing | Silkscreen Printing |

|---|

| Setup Time | Longer setup process; involves multiple steps for achieving high precision. | Quicker to set up, translating to faster initial turnarounds for small orders. |

| Production Speed | Faster once setup is complete; efficient for large volume runs. | Slower print per unit; better suited for specialty custom cookie packaging. |

Offset printing's time-intensive setup pays off with higher throughput, making it vital for productions needing quick scaling up such as custom cake boxes with logo. The adaptability of silkscreen gears it towards bespoke, rapid-adjustment projects, ideal for personalized gable boxes.

Material Compatibility

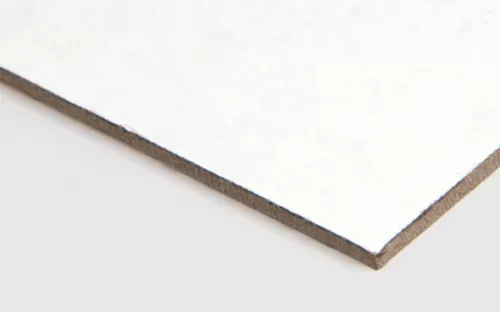

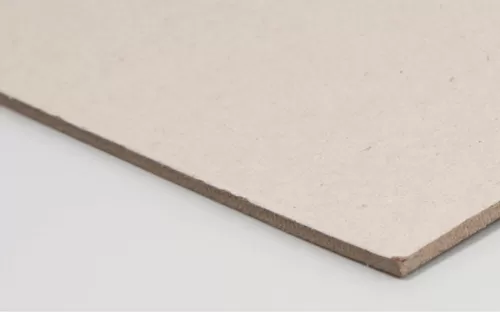

Packaging varies widely in terms of materials used, necessitating a careful selection of printing technology probable in dealing with diverse bases like custom boxes for clothing and custom jewelry packaging.

| Compatibility | Offset Printing | Silkscreen Printing |

|---|

| Best Materials | Paper-based, flat surfaces; ideal for custom take out boxes. | Various substrates, including curved or textured surfaces, like custom tea box. |

| Challenges | Limited to non-textured surfaces; restricted in using certain finishes. | Complex setups for multi-colored prints; challenges aligning fine details. |

Offset printing thrives on paper products and flat surfaces due to its precise plate-based process, frequently used by custom printed pizza boxes manufacturers. Silkscreen's adaptability to different textures and materials allows it to decorate complex surfaces like parts of custom dog soap boxes.

Conclusion

Understanding the diverse advantages of offset and silkscreen printing is essential for making informed decisions about your packaging needs. Whether considering cosmetic box packaging or custom jewelry packaging, each method offers unique strengths suited for different applications. Offset is your go-to for high-volume, detailed prints on flat surfaces, while silkscreen excels in delivering vibrant, tactile designs across various materials. By choosing the right method, businesses can achieve both aesthetic brilliance and operational efficiency, enhancing their brand's visual impact in the competitive marketplace. For more insights, you can visit reliable sources below.

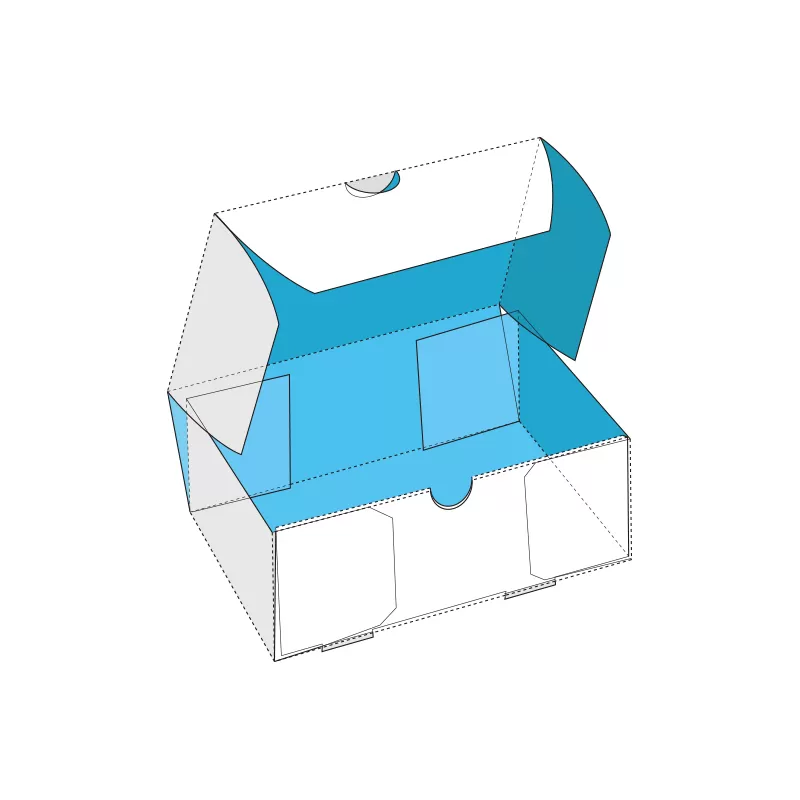

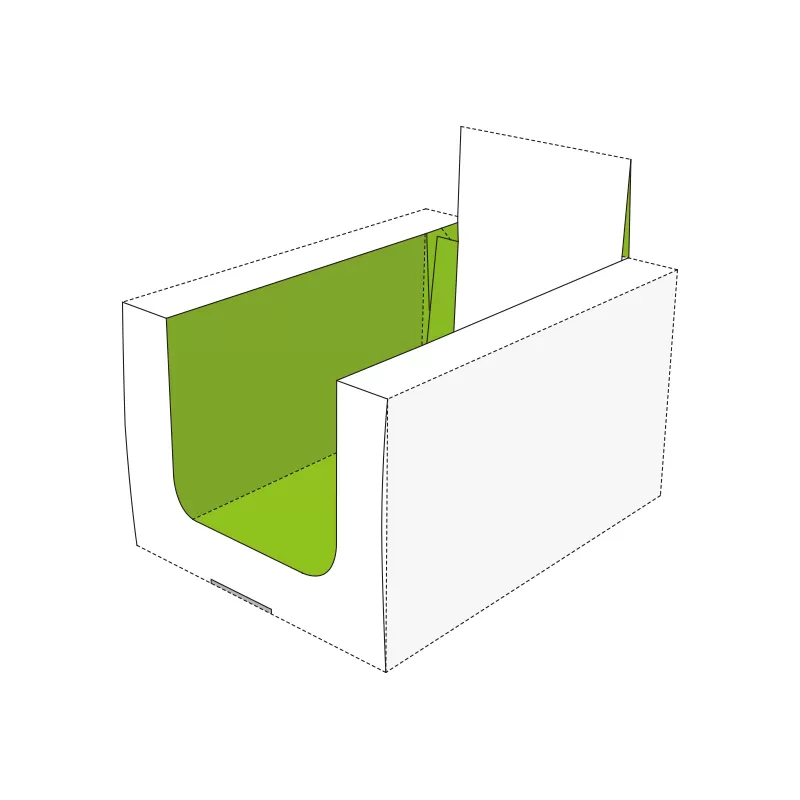

Our packaging experts design and engineer innovative structures tailored to your product and branding.Explore design & engineering

Our packaging experts design and engineer innovative structures tailored to your product and branding.Explore design & engineering Our packaging design specialists create exceptional custom artwork that showcase and bring your branding to the next level.Explore design & engineering

Our packaging design specialists create exceptional custom artwork that showcase and bring your branding to the next level.Explore design & engineering Create physical samples and 3D interactive prototypes final product packaging before making a final decision.Explore design & engineering

Create physical samples and 3D interactive prototypes final product packaging before making a final decision.Explore design & engineering