In the world of packaging, choosing the right box for your product distribution is essential to balance protection, cost, and presentation. Two common types of packaging are rigid boxes and corrugated boxes, each serving specific needs based on industry and product type. While rigid boxes are known for their luxury appeal, corrugated boxes remain a staple for shipping due to their cost-effectiveness and strength. This article will explore the differences between rigid and corrugated boxes, focusing on strength and durability, cost, aesthetic appeal, sustainability, and best use cases to help businesses make informed decisions when selecting packaging solutions.

Strength and Durability

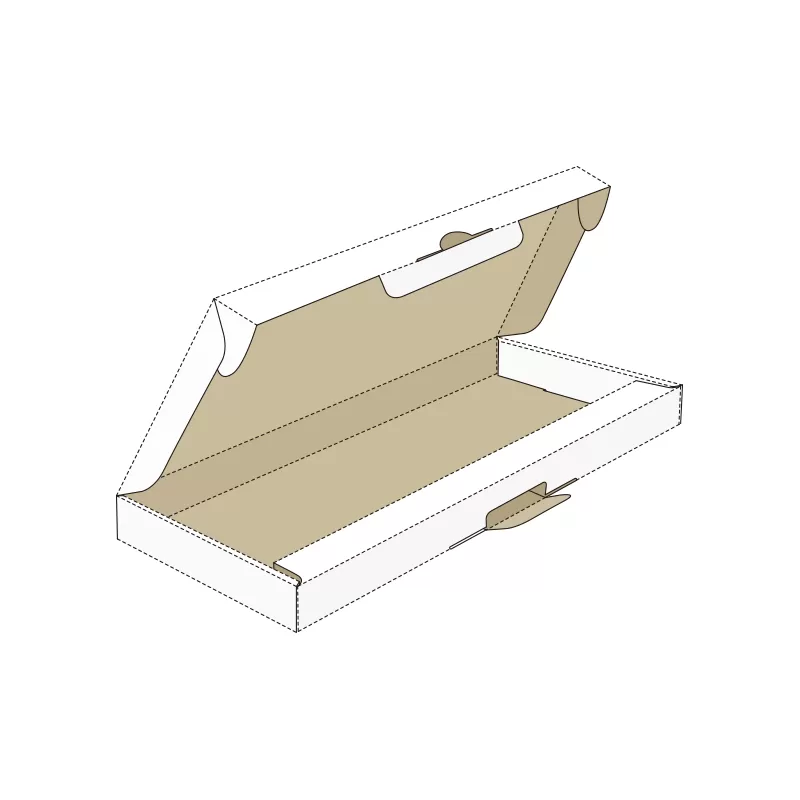

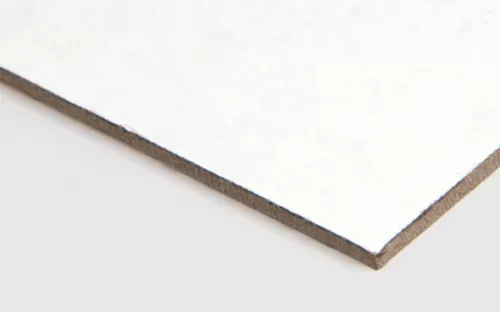

The primary consideration in packaging is ensuring that the box can protect its contents during transit. Rigid boxes, often used for luxury jewelry boxes wholesale or custom candle boxes, are made from highly durable materials like chipboard that provide significant structural integrity. On the other hand, corrugated boxes consist of a fluted corrugated sheet sandwiched between two linerboards, making them ideal for shipping heavier items like electronics or multiple units of soap boxes wholesale.

| Box Type | Material | Strength |

|---|

| Rigid Boxes | Chipboard | High compressive strength |

| Corrugated Boxes | Fluted fiberboard | High impact resistance |

Rigid boxes, used in custom luxury gift boxes, are prized for their sturdy construction, making them suitable for high-value items that need additional protection and an upscale presentation. In contrast, corrugated boxes, often employed in custom bakery packaging and custom wine boxes, are designed to withstand environmental forces and are economically advantageous for large-volume shipping.

Cost Differences

When budgeting for packaging, understanding cost implications is crucial. Corrugated boxes generally offer a more affordable solution compared to rigid boxes, especially when buying in bulk. This affordability makes them a preferred choice for companies needing beer shipping boxes or custom apparel boxes.

Conversely, rigid boxes are more cost-intensive to produce due to their superior materials and manufacturing processes. They are often utilized in situations where brand image and product experience are prioritized, such as in high-end cosmetic box packaging.

| Box Type | Cost Efficiency | Ideal Use |

|---|

| Rigid Boxes | Higher cost | Luxury goods |

| Corrugated Boxes | Cost-effective | Bulk shipments |

The decision between these options should consider the product value, brand positioning, and customer expectations. Companies may opt for rigid boxes for custom jewelry packaging and personalized gable boxes, where the customer unboxing experience adds value to the product.

Aesthetic Appeal

Packaging plays a vital role in attracting customers and reinforcing brand identity. Rigid boxes stand out for their clean lines, quality finish, and customizability. They are commonly used for custom gift boxes with logo and personalized shoe boxes because they offer a high-end appearance that communicates exclusivity and luxury.

Corrugated boxes, though typically less elegant, can be highly customized in terms of printing and sizing, enhancing their appeal for mass-market products like custom printed pizza boxes and 6 pack beer carrier. Advanced printing techniques can transform corrugated surfaces with engaging designs for custom garment boxes and custom printed soap boxes.

Sustainability Factors

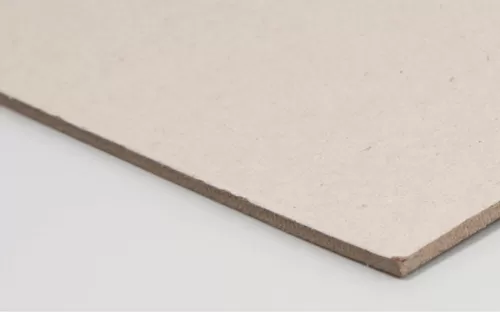

Environmental sustainability is an increasingly important consideration in packaging. Corrugated boxes are often made from recycled materials and are fully recyclable, making them an eco-friendly option and commonly used for custom clothing boxes.

In contrast, rigid boxes, though recyclable, may involve more resource-intensive processes. Brands prioritizing sustainability may opt for creative designs in corrugated materials that still offer a premium feel, especially in industries such as custom chocolate box and personalized pastry boxes.

| Box Type | Environmental Impact |

|---|

| Rigid Boxes | Moderate, less recycled content |

| Corrugated Boxes | High, more recycled content |

Best Use Cases

The choice between rigid and corrugated boxes depends largely on the product type, shipping requirements, and brand goals. Rigid boxes are well-suited for custom magnetic closure boxes and magnetic flap gift box wholesale, where presentation and product protection are key.

Corrugated boxes, with their versatility and strength, excel in shipping diverse products such as waterproof box for electronics and custom dog soap boxes. Industries like food delivery and clothing often leverage the affordability and resilience of corrugated packaging for custom take out boxes and custom tea box shipping.

Brands seeking a blend of aesthetics and functionality may explore innovative designs that incorporate rigid boxes with display boxes for sale features or pillow box packaging style to enhance their market appeal.

Conclusion

Choosing between rigid boxes and corrugated boxes requires an understanding of the specific needs of your products, from cost and strength to presentation and sustainability. Each packaging type serves unique purposes and complements various business models. Understanding these differences allows companies to align their packaging choices with their broader strategic objectives, whether aiming for cost efficiency or brand prestige. Ultimately, the key is to select a packaging solution that effectively balances protection, costs, and brand presentation, enhancing both customer satisfaction and business success.

Our packaging experts design and engineer innovative structures tailored to your product and branding.Explore design & engineering

Our packaging experts design and engineer innovative structures tailored to your product and branding.Explore design & engineering Our packaging design specialists create exceptional custom artwork that showcase and bring your branding to the next level.Explore design & engineering

Our packaging design specialists create exceptional custom artwork that showcase and bring your branding to the next level.Explore design & engineering Create physical samples and 3D interactive prototypes final product packaging before making a final decision.Explore design & engineering

Create physical samples and 3D interactive prototypes final product packaging before making a final decision.Explore design & engineering