Designing Custom Shoe Boxes for Brand Differentiation

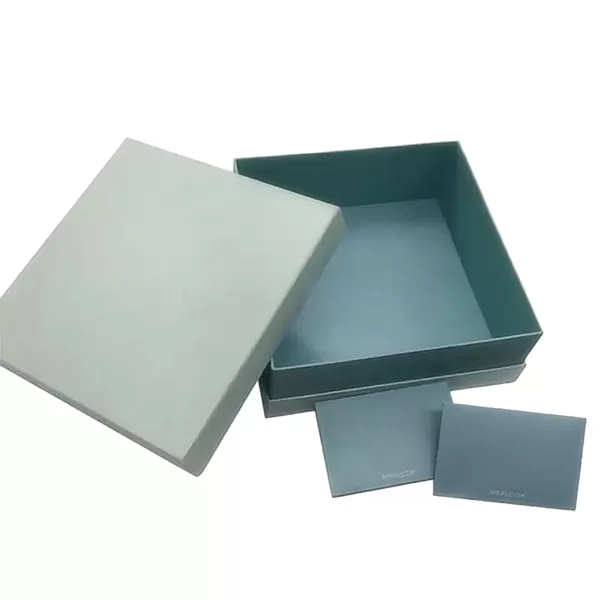

In the competitive world of footwear retail, custom printed shoe boxes aren't just packaging—they're a powerful branding tool that elevates your product from ordinary to unforgettable. Imagine unboxing a pair of sneakers that arrives in a bespoke shoe boxes design emblazoned with your logo, vibrant patterns, and premium finishes that whisper luxury. Whether you're a startup sneaker brand or an established label, personalization is key. Add magnetic closures for a satisfying snap, a shoe box with handle for easy carrying, or eco-friendly options to appeal to conscious consumers. By investing in custom luxury shoe boxes, you boost perceived value, reduce returns, and foster customer loyalty.

Why Personalized Shoe Boxes Are Revolutionizing E-Commerce Packaging

Personalized shoe box designs are transforming the unboxing experience, making every delivery feel like a gift tailored just for the customer. In an era where online shoe sales surge past $100 billion annually, standing out amid plain brown boxes is crucial. These custom shoe box packaging solutions allow brands to infuse personality—think boxes etched with the buyer's initials, motivational quotes, or AR-enabled designs that scan to reveal styling tips. Beyond aesthetics, they protect delicate heels and soles during transit, minimizing damage claims that plague standard shipping.

Crafted from recyclable paperboard or luxurious matte finishes, custom made shoe boxes align with sustainability trends, appealing to 78% of shoppers who prefer eco-conscious brands. For wholesalers, bulk orders of wholesale shoe box options mean scalable branding without breaking the bank, with features like die-cut windows to tease the treasure inside. This isn't mere wrapping; it's storytelling that extends your brand's narrative, encouraging shares on Instagram and TikTok. Partnering with experienced shoe box packaging suppliers or custom shoe box manufacturers ensures quality and innovation.

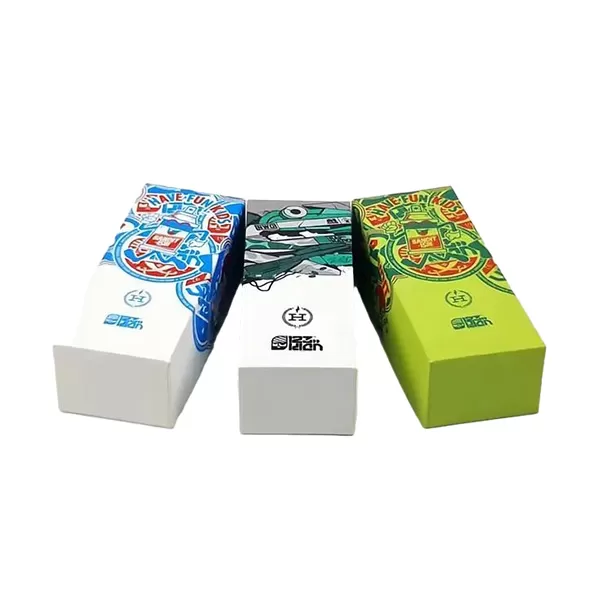

Paperboard Printed Shoe Boxes

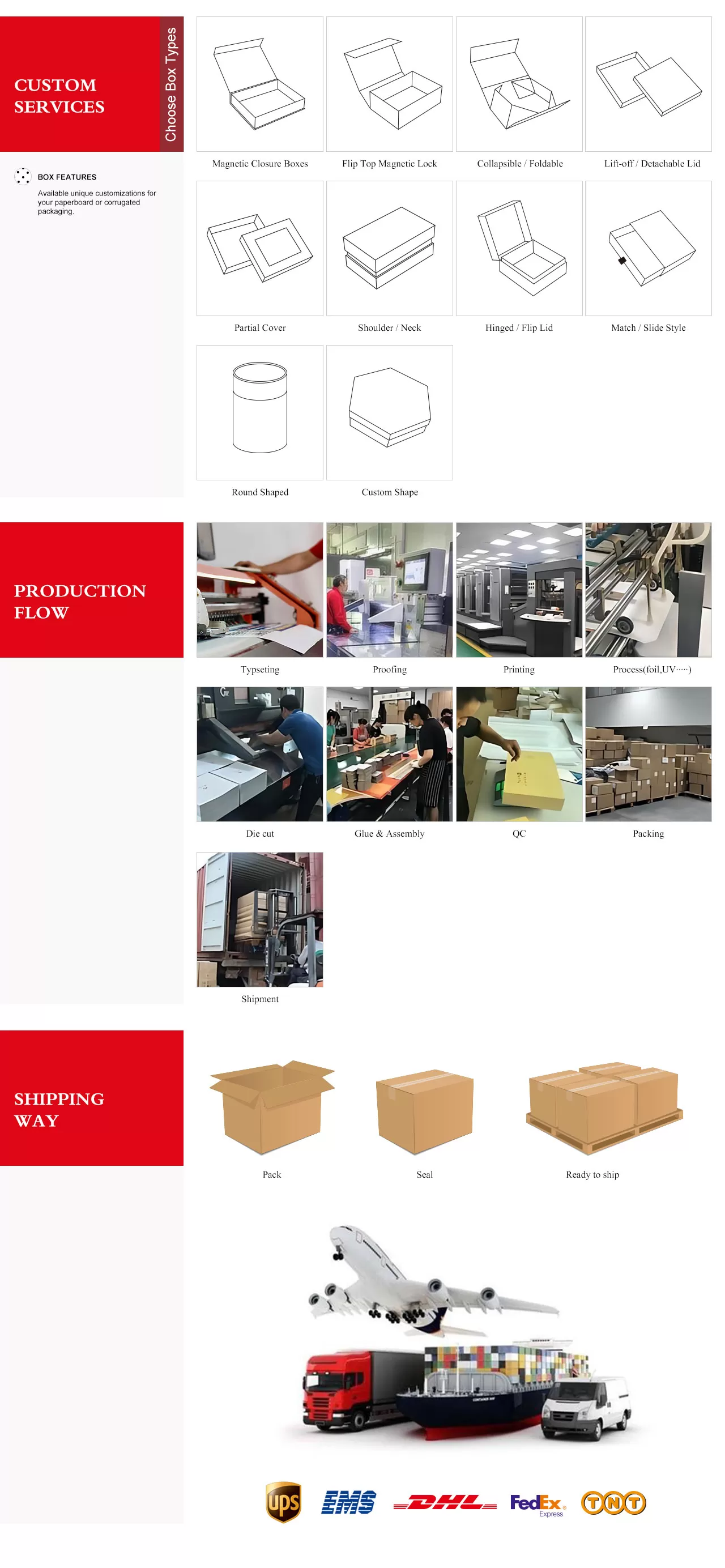

-

Premium-grade textured paper stock primarily used for wrapping rigid boxes.

-

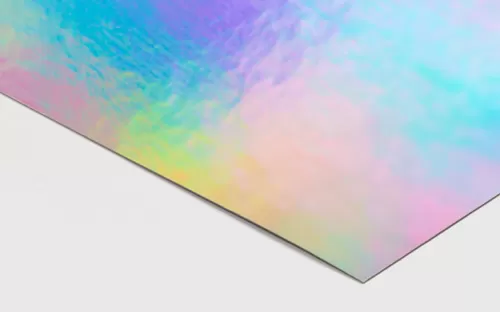

Specialty paper material featuring a glossy or matte holographic laminated surface.

-

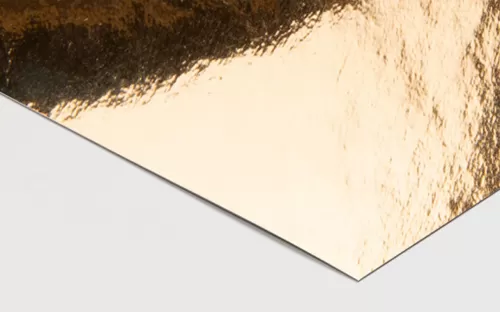

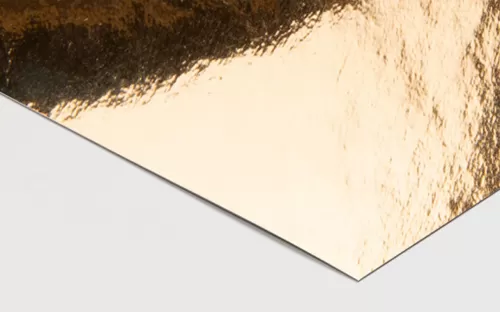

Specialty paper material featuring a glossy or matte metallic laminated surface.

-

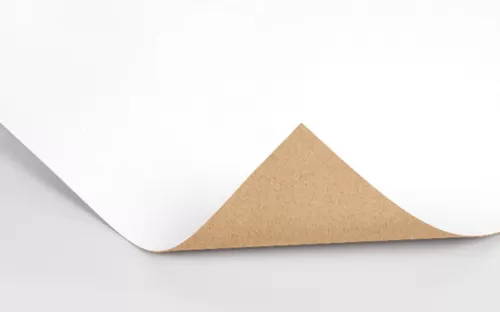

Kraft paper with an uncoated bleached topside and unbleached bottom side.

-

Kraft paper with a coated bleached topside for high-quality print and unbleached bottom side.

-

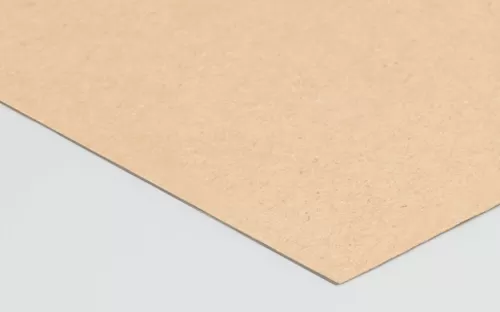

Unbleached kraft paper with no coating. Made from a mixture of virgin and recycled paper pulp.

-

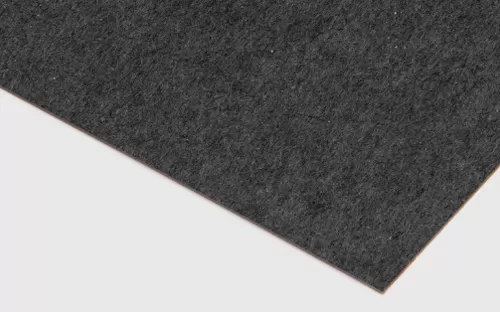

Black dyed kraft paper made from a mix of virgin and recycled pulp, coated on both sides for printing.

-

Bleached kraft paper made from a mix of virgin and recycled pulp with coating on both sides for printing.

-

Kraft paper made from a mix of virgin and recycled paper pulp, coated on both sides for printing.

-

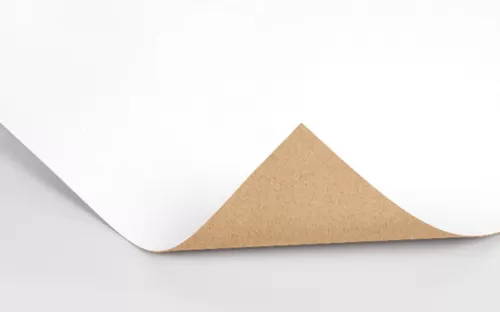

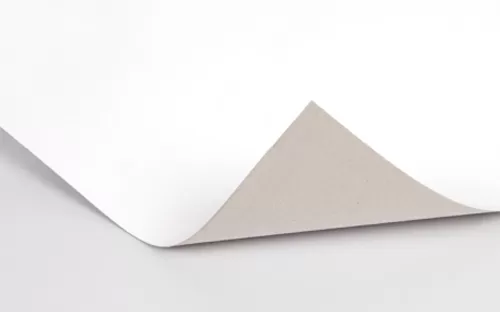

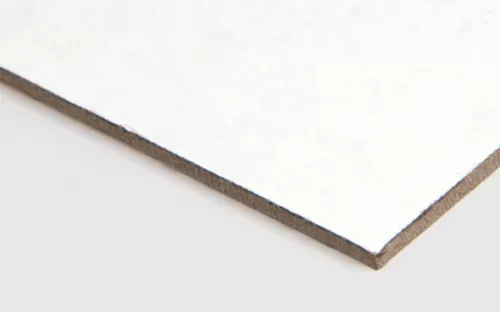

Duplex paperboard coated on one side and made from 90% recycled paper pulp.

-

Duplex paperboard made from 90% recycled paper pulp with a white surface for high-quality printing.

-

Premium-grade bleached white paperboard coated on two sides for high-quality printing and finishes.

-

Premium-grade bleached white paperboard coated on one side for high-quality printing and finishes.

Corrugated Printed Shoe Boxes

-

Bleached white board with a brilliant white finish for high-quality vibrant printing.

-

Coated kemi white corrugated board, semi-gloss linerboard that features a brilliant white and smooth surface for high-quality printing.

-

Coated, textured linerboard featuring an off-white surface for high-quality printing.

-

Uncoated and unbleached kraft linerboard made from a mixture of virgin and recycled paper pulp.

Plastic Printed Shoe Boxes

-

Durable and strong plastic with high resistance to heat, chemicals and water.

-

Green alternative to traditional plastics. Biodegradable and made from renewable resources.

-

High impact resistant and rigid thermoplastic perfect for packaging heavy products.

-

High tensile strength plastic with food-safe capabilities, made from recycled material.

-

Low density polyethylene (LDPE) plastic is a high clarity material commonly used for producing shopping bags and food wrapping.

-

Flexible, dense, heat-resistant and high tensile strength plastic with high-quality printing capability.

-

Durable, strong tensile strength and low moisture absorption plastic with a matte finish.

-

Strong and lightweight crystal clear thermoplastic with high-quality printing capability.

Print Methods of Printed Shoe Boxes

-

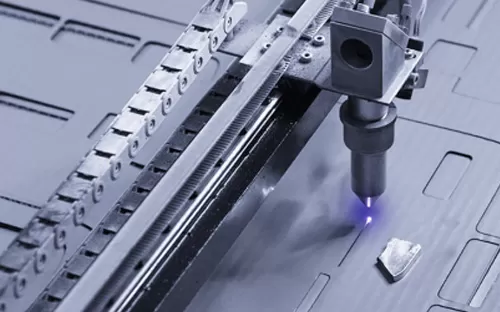

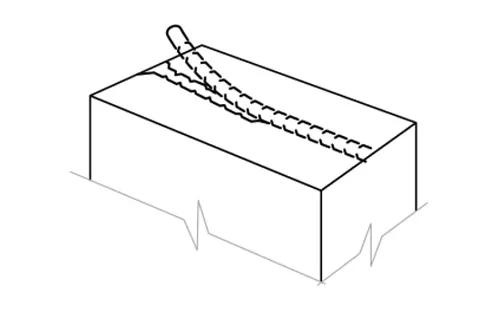

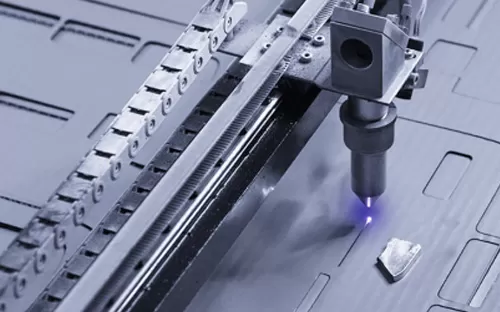

Quick engraving process utilizing a high heat laser to vaporize designs on the surface of any material.

-

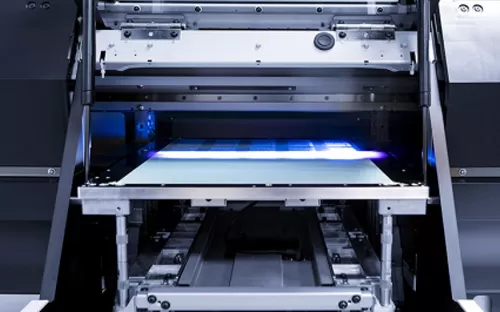

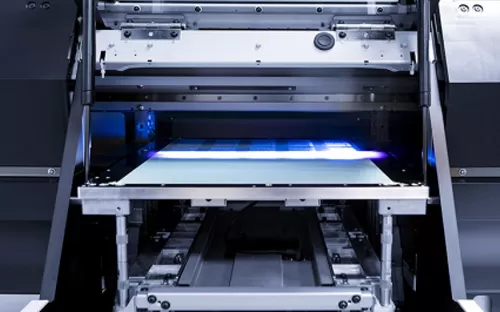

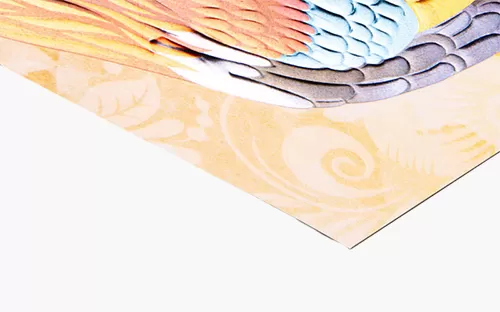

Fast-drying printing method using ultraviolet lights to cure inks which results in a gloss finish.

-

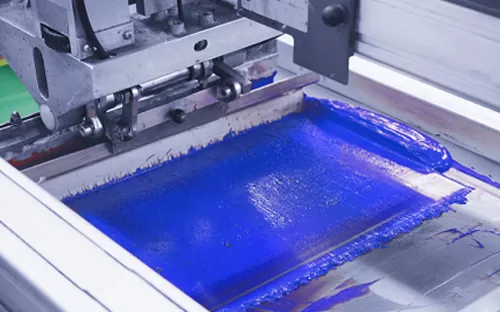

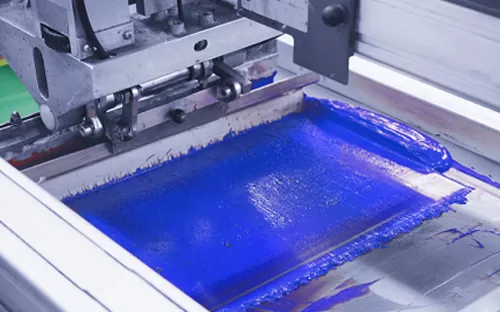

Stenciling printing method using stacked layers of color. Commonly used for one to two color prints.

-

Transferred electronically requiring no printing plates for cost and time efficient printing.

-

Rubber printing plates are used to stamp designs on paper for cost and time efficient printing.

-

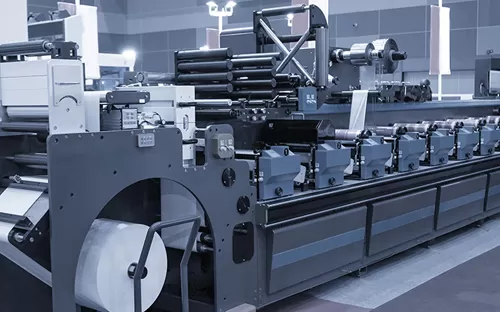

A printing plate and rubber blanket is used to transfer designs to paper for high-quality printing.

Inks of Printed Shoe Boxes

-

Pure color based on specific ink formulas to consistenly and precisely print color.

-

Non-eco-friendly ink comprised of oil and pigment that provides high-quality color output.

-

Bright and opaque ink that reflects and emits lights from absorbing ultraviolet energy.

-

Comprised of water and pigment that provides high-quality color output and is 100% eco friendly.

Coating of Printed Shoe Boxes

-

Clear coating applied using the CMYK printing method. Available in gloss, satin, or matte.

-

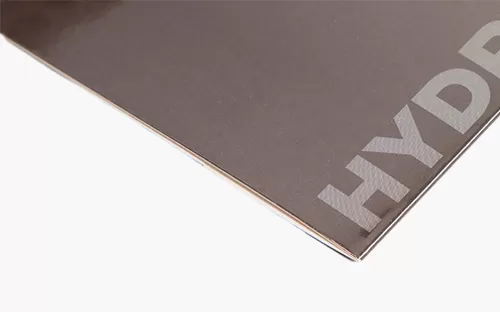

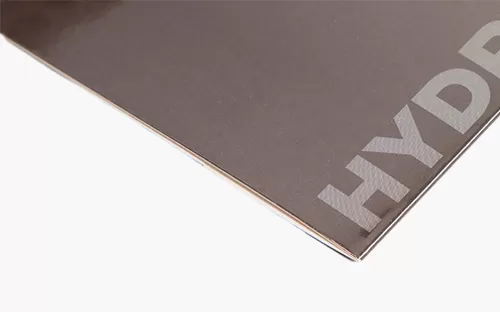

Soft to the touch coating that creates a velvety texture for a more tactile appeal.

-

UV coating that is applied to a specified area and cured using ultraviolet light.

-

Fast-drying coating cured with ultraviolet light. Available in gloss or matte finish.

-

Clear, fast-drying, water-based, and eco-friendly coating. Available in gloss or matte finish.

Lamination of Printed Shoe Boxes

-

Soft to the touch lamination similar to peach skin. Available in a satin or matte finish.

-

Laminated BOPP film that is scratch, scuff, and fingerprint resistant. Cost-effective option.

-

Laminated protective film that adheres to the surface of packaging materials to maximize durability.

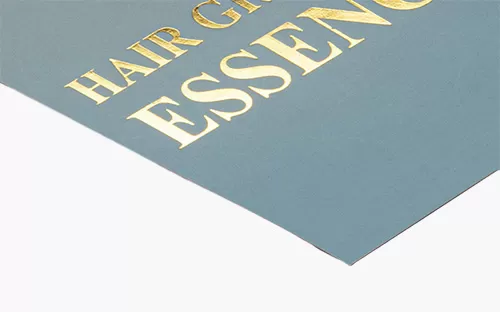

Special Options of Printed Shoe Boxes

-

Die-cut shape is layered with plastic film to feature a window showcasing the product inside.

-

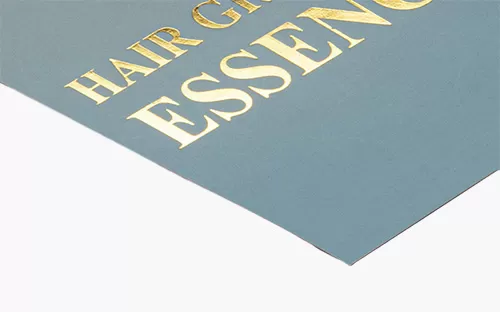

Combination between embossing and foil stamping. It creates a 3D motif that features a foil finish.

-

Form of relief printing in which a die is pressed on the back of the material to form a raised motif.

-

Form of relief printing in which dies is pressed on the front of the material to form a raised motif.

-

Form of relief printing in which dies is pressed on the back of the material to form a raised motif.

-

Form of relief printing in which foil is transferred to a surface by pressing onto UV curable adhesives.

-

Form of relief printing in which foil is transferred to a surface at high temperatures.

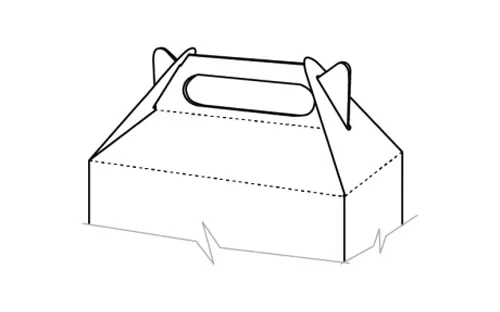

Top Closure of Printed Shoe Boxes

-

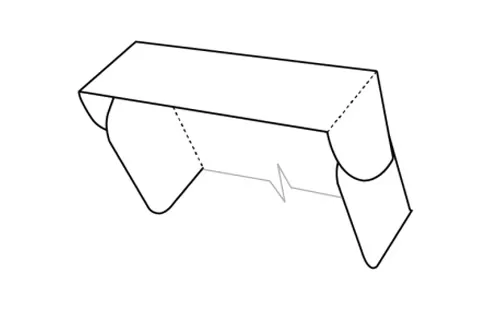

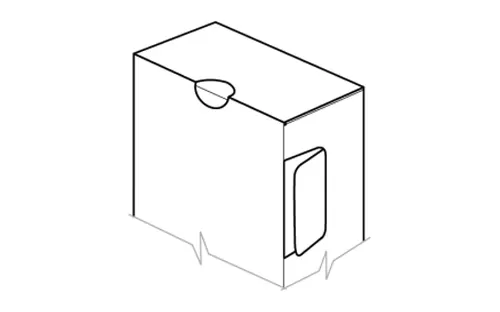

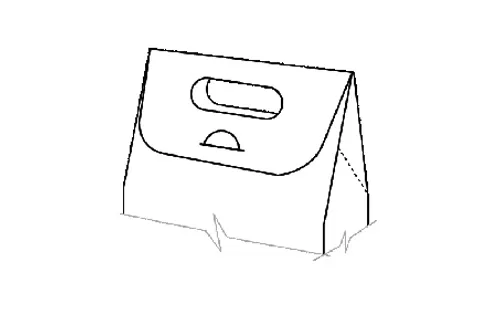

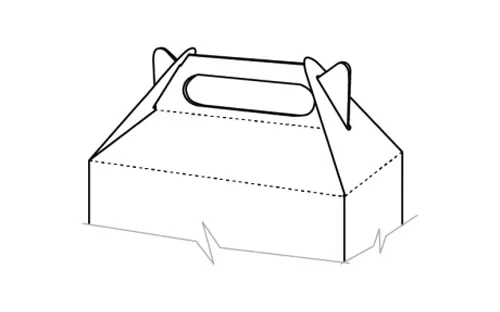

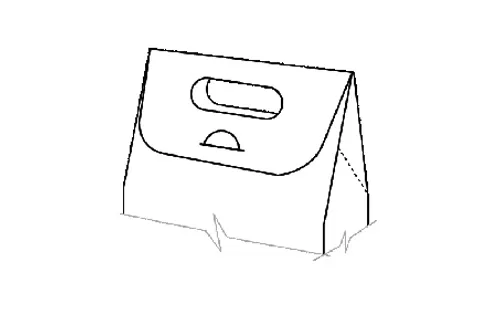

Gable top design featuring tabs that interlock onto a handle for convenient sealing and carrying.

-

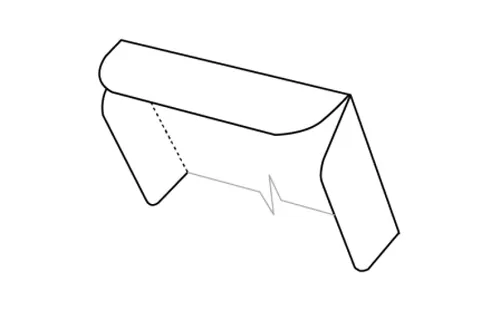

Gable top design that features a sticky lock tab for convenient resealing and opening.

-

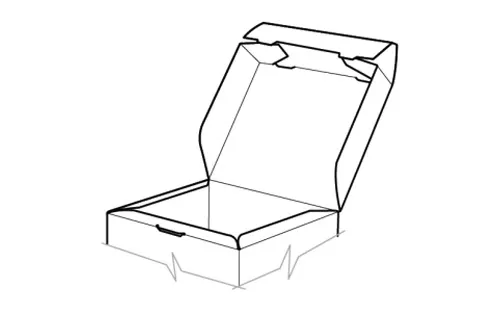

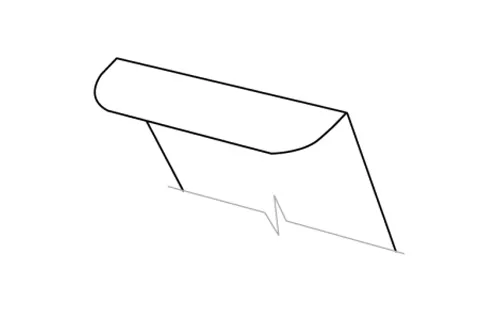

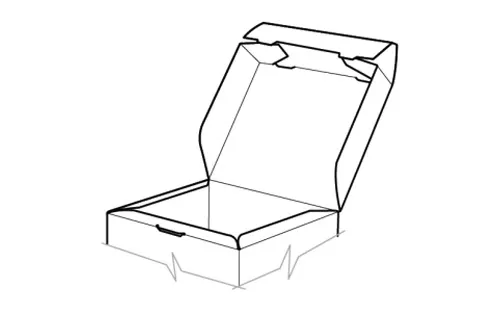

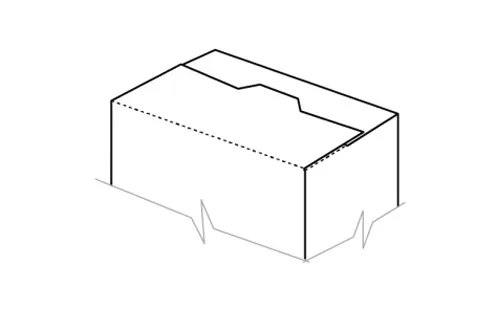

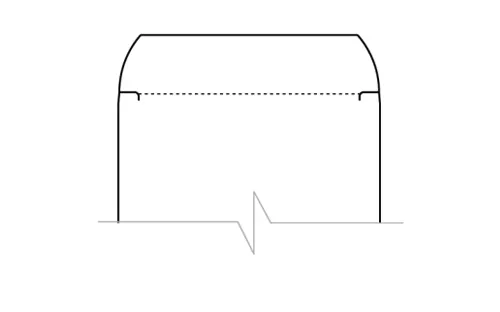

Tuck top design that features a lock at the front panel that pops up to open the packaging.

-

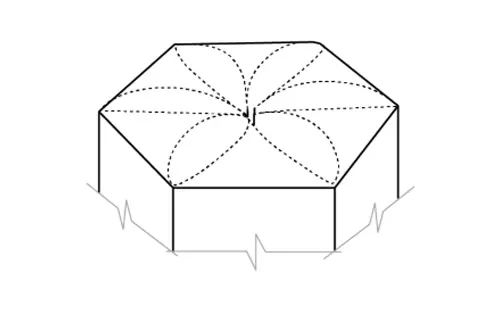

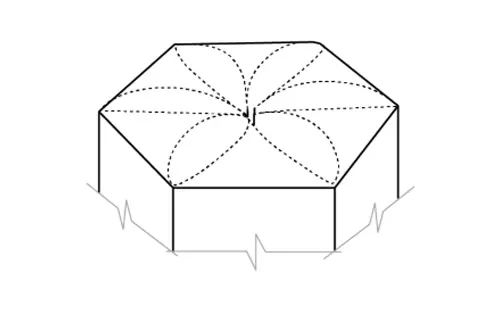

Unique design that features flaps that interlock to create a flower that seals the top.

-

Open flap design that features flaps of the same length that overlap for sealing.

-

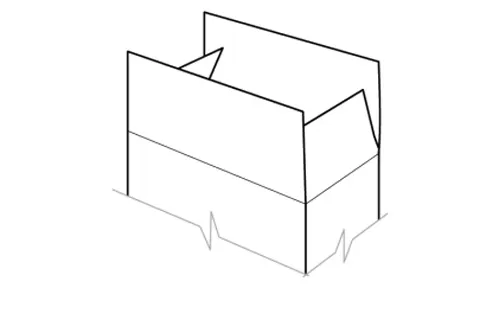

Open flap design that features four flaps of the same length that meet in the middle.

-

Tuck flap design features panels that are wide enough to overlap with a sticky flap to lock together.

-

Tuck flap design featuring two overlapping sticky flaps that slide on top of each other for easy sealing.

-

Tuck top design that features a gusset structure for sturdier corners and convenient sealing.

-

Tuck top design features small slits on either side of the fold to lock the top in place.

-

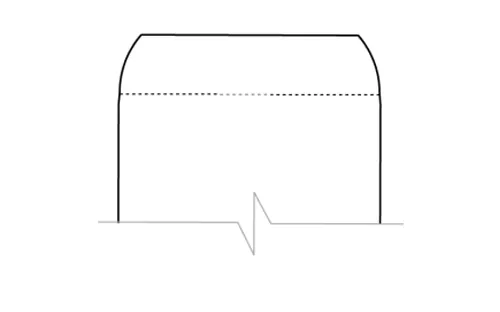

Tuck top design that uses the friction of the material for convenient sealing and opening.

Bottom Closure of Printed Shoe Boxes

-

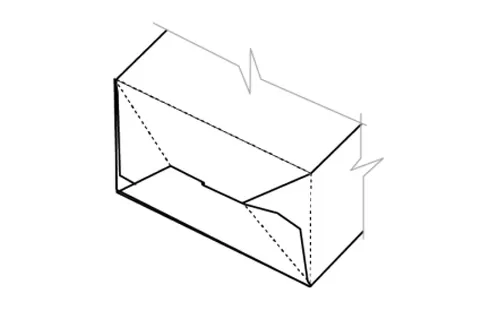

Open flap design that features flaps of the same length that overlap for sealing.

-

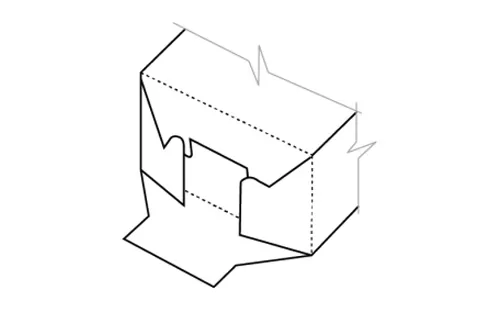

Interlocking design features pre-glued panels for easy assembly without using adhesive.

-

Four flaps featuring a tab to fold together and create a secrue lock without using adhesive.

-

Open flap design that features flaps of the same length that overlap for sealing.

-

Open flap design that features four flaps of the same length that meet in the middle.

-

Tuck flap design featuring two overlapping sticky flaps that slide on top of each other for easy sealing.

-

Tuck top design features small slits on either side of the fold to lock the top in place.

-

Tuck top design that uses the friction of the material for convenient sealing and opening.

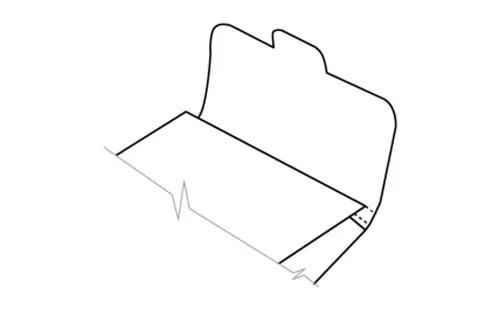

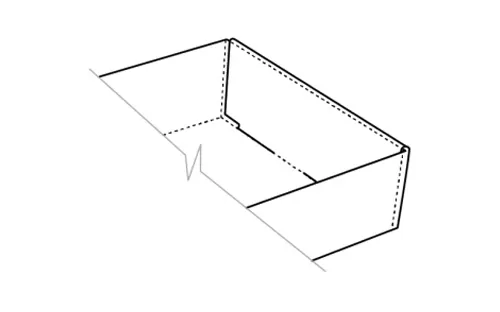

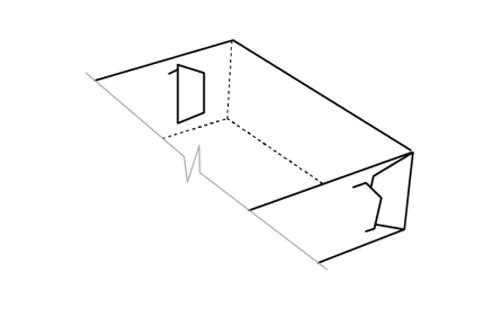

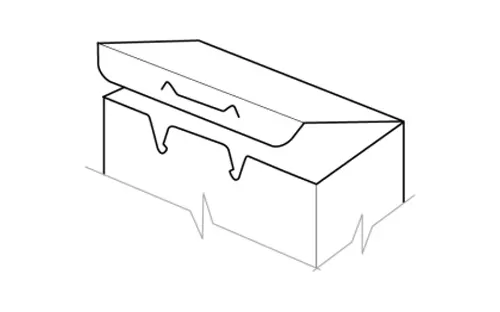

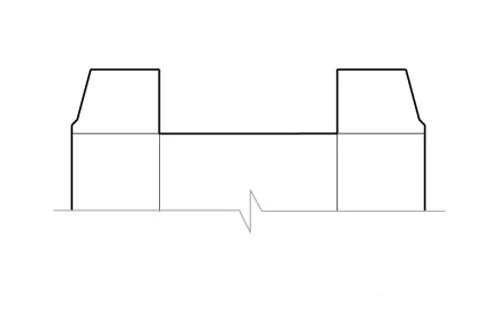

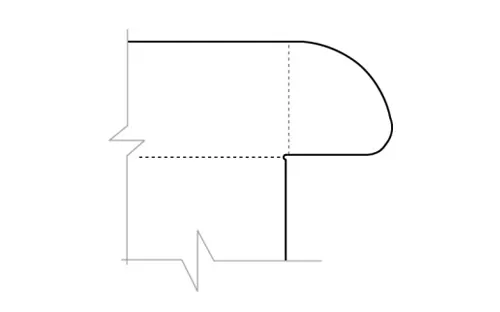

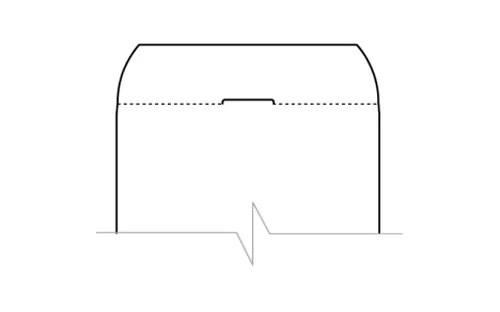

Tray & Lids of Printed Shoe Boxes

-

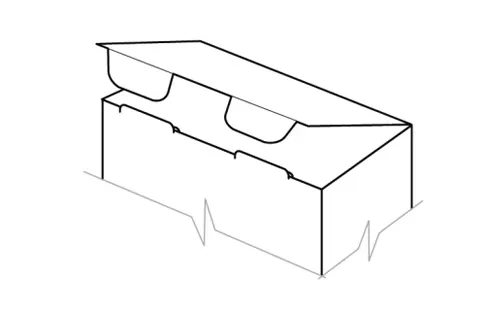

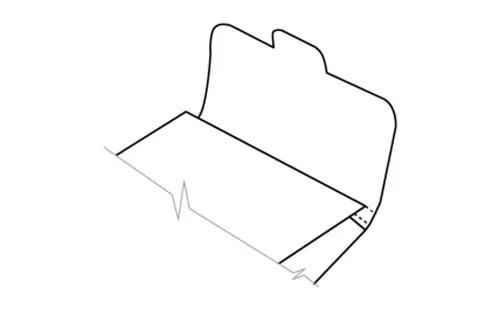

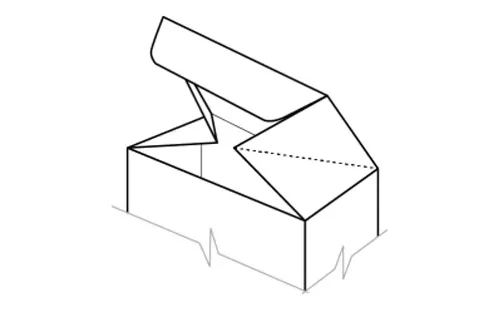

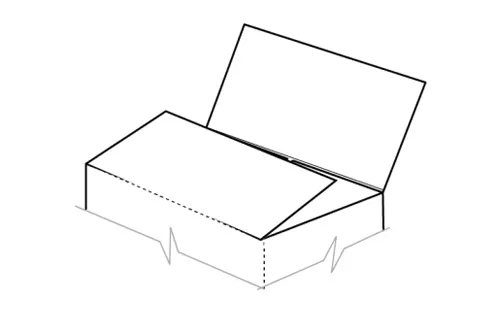

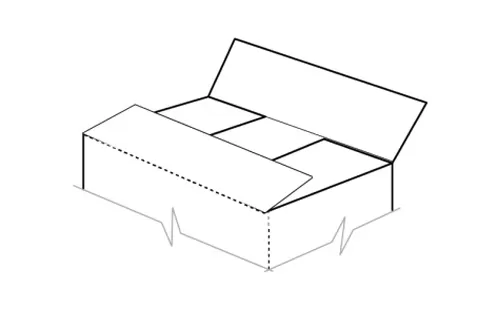

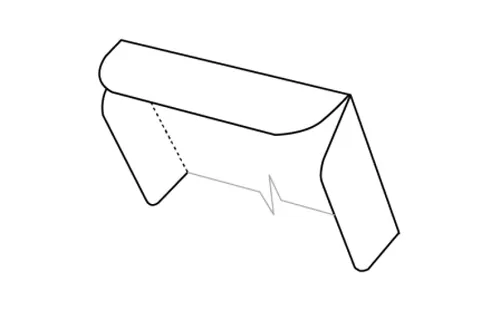

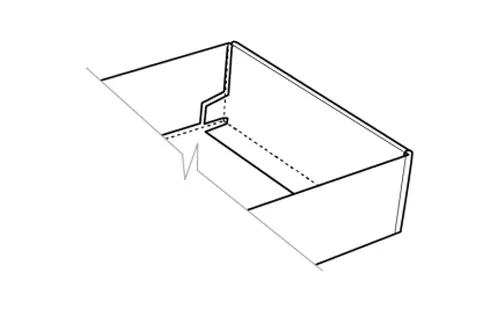

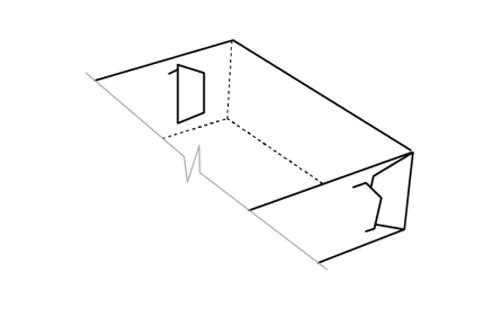

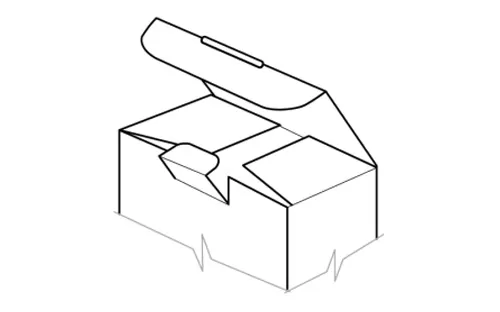

Roll end design featuring a tab on the upper piece that self-locks for convenient and secure assembly.

-

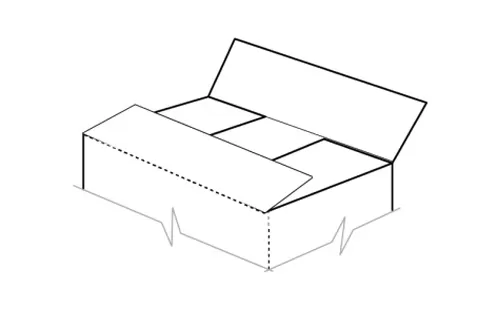

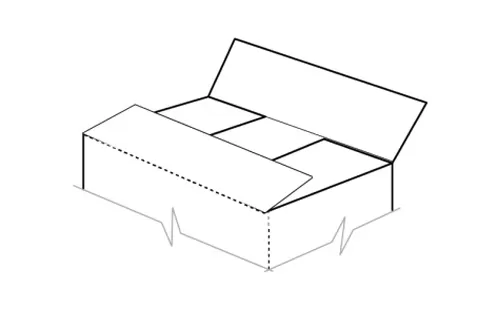

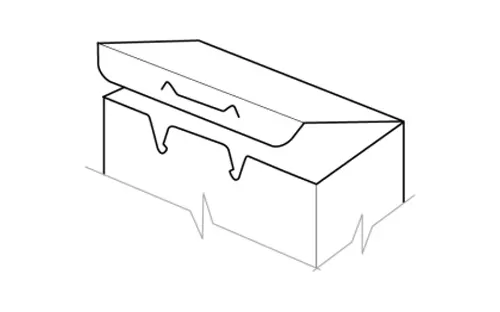

Tuck top design featuring hinged tabs and side flaps for convenient and secure sealing.

-

Tuck top design features three tabs that lock the top for secure sealing capabilities.

-

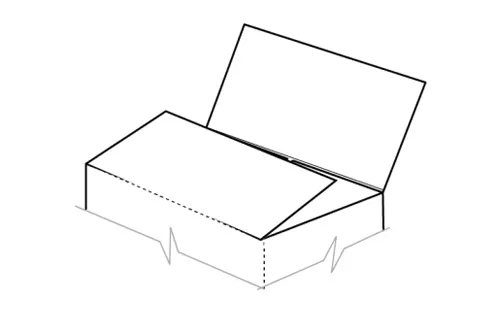

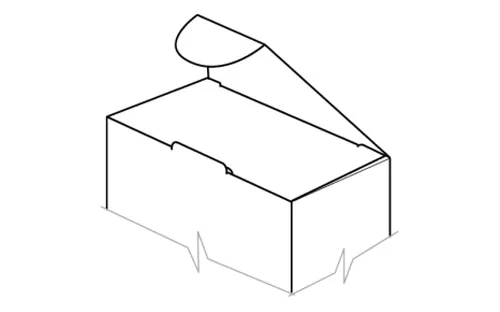

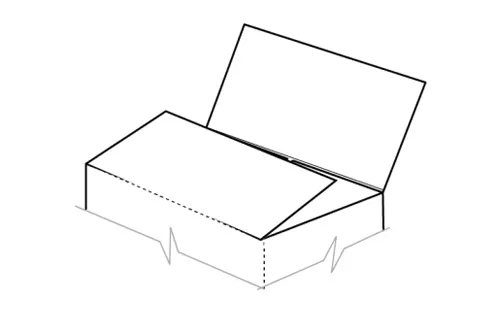

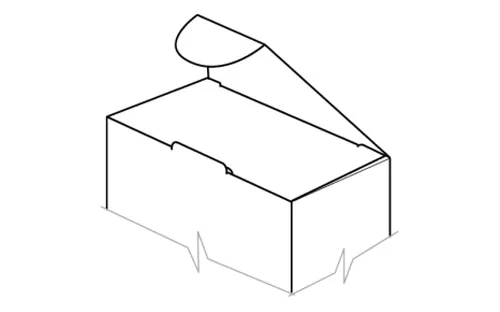

Tuck top design featuring a hinged lid that seals the top of a box, without side flaps.

-

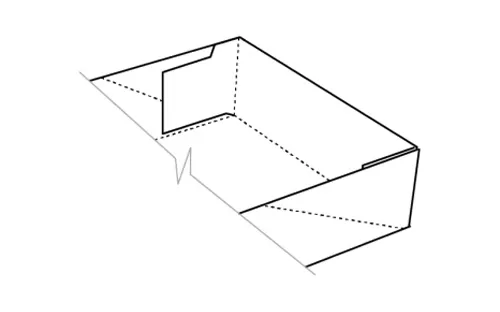

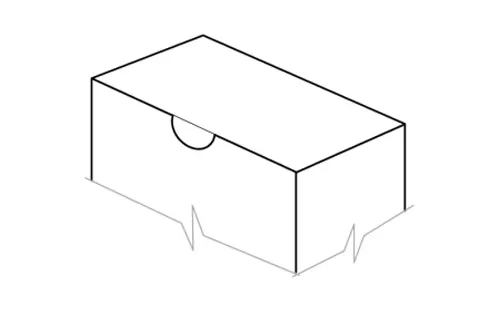

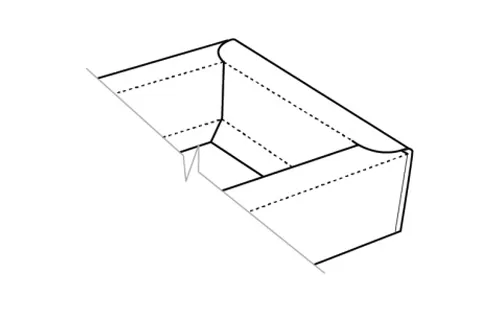

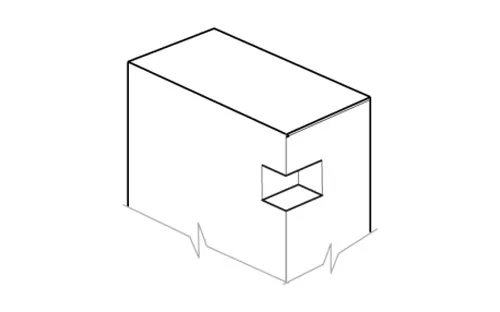

Collapsible design that features pre-glued corners for easy assembly and optimal protection.

-

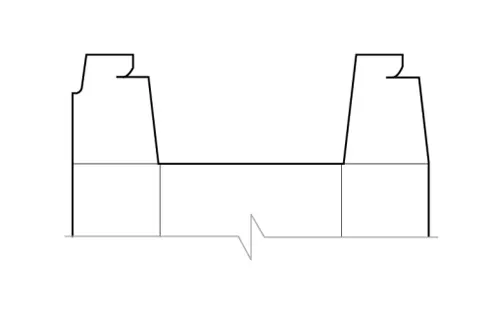

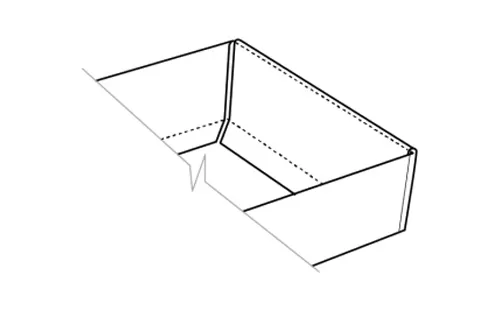

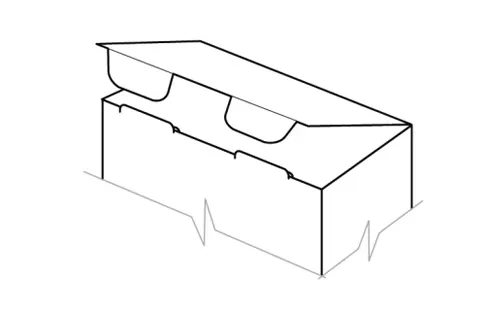

Double frame tray design featuring double layers for added protection and convenient assembly.

-

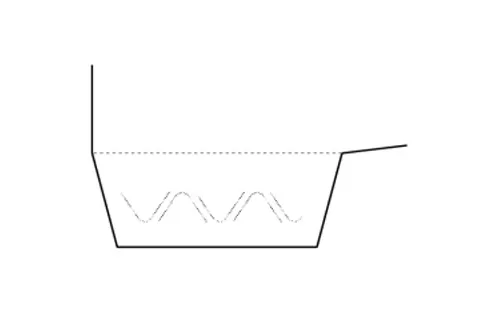

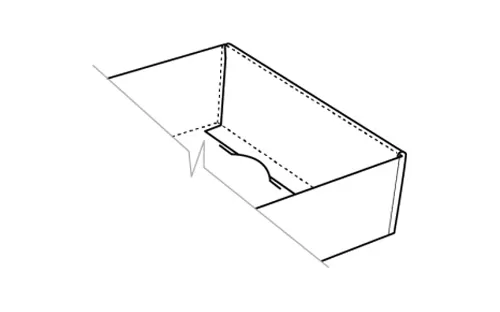

Double-walled design featuring glue on the side walls for easy and convenient assembly.

-

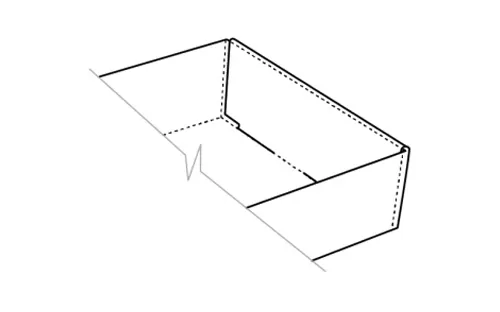

Double-walled design featuring a self-lock design that doesn't require adhesive.

-

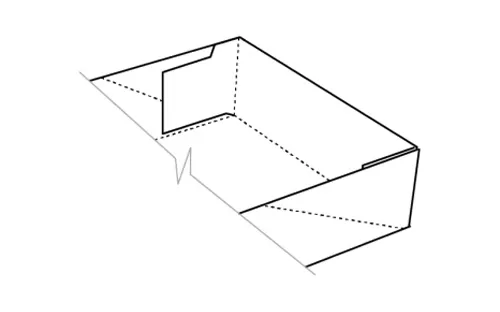

Triple-layer, strong-walled structure featuring side panels that roll over to assemble the base.

-

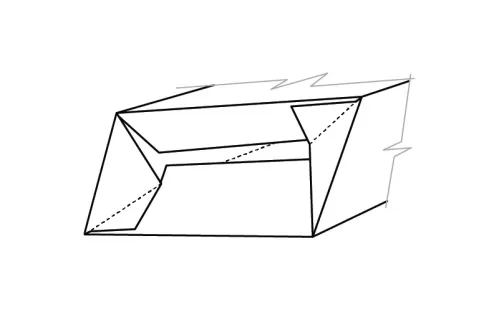

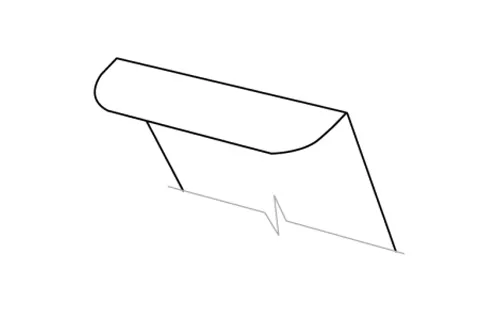

Self-locking, roll end design, featuring 30% less material than a standard roll end base.

-

Self-locking design that features two slits and two tabs that interlock securely without using adhesive.

Miscellaneous Features of Printed Shoe Boxes

-

Small holes on the surface of a paper material to provide a convenient way to tear open.

-

Tuck top design featuring a slit for the panel to lock onto to create secure sealing capabilities.

-

Added to a range of boxes to create a filler space for products to rest on and remain in place.

-

Matchbox design featuring a lock for child safety unlocked by pressing down a side tab.

-

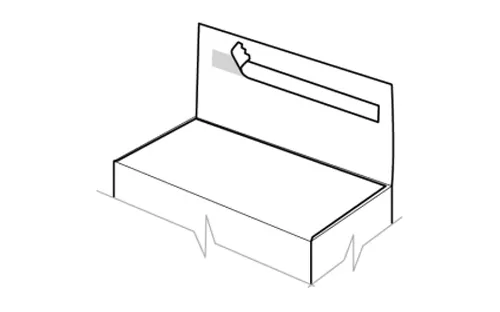

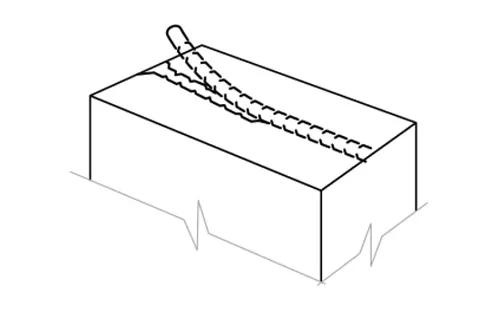

Perforated strip on the outer panel that can be peeled back for a satisfying unboxing experience.

-

Added to seal end packaging to offer convenient sealing or returnability of products.

-

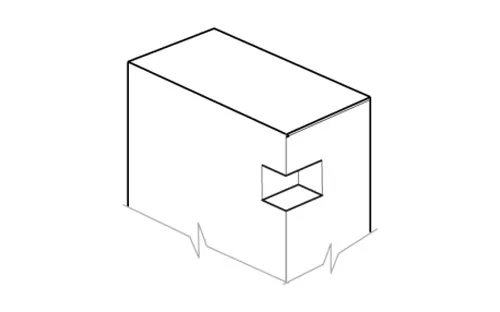

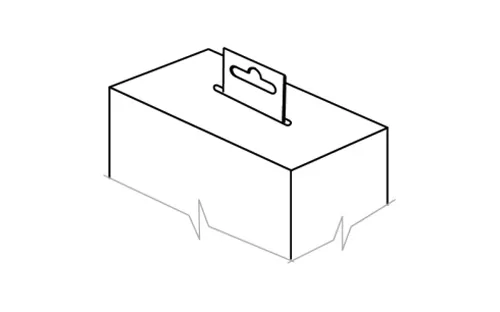

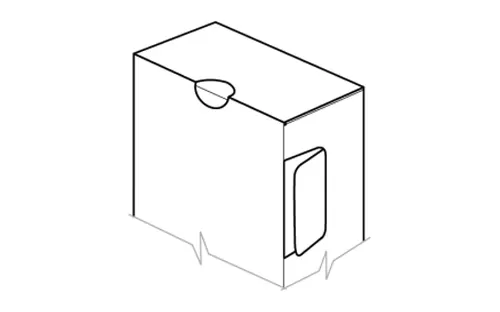

Gusset design featuring a die-cut hole for carrying and handling packaging at ease.

-

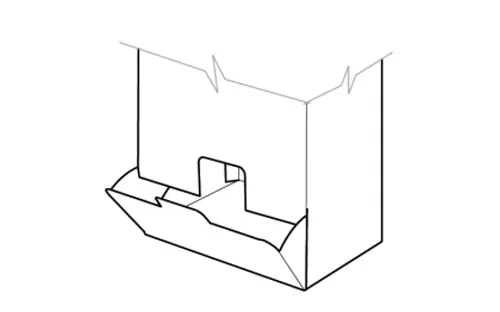

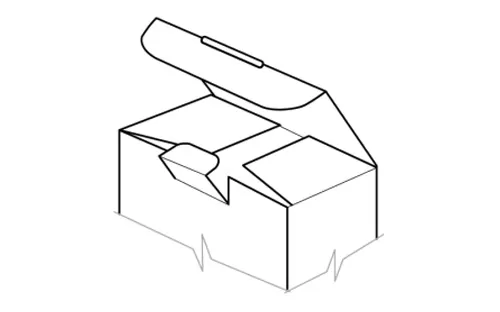

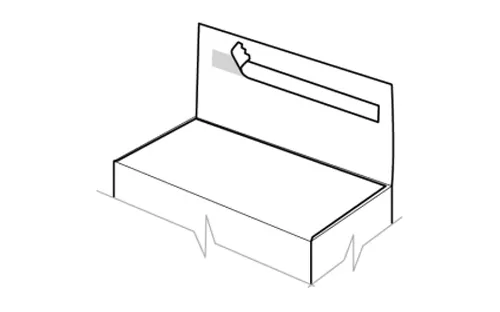

Tuck top, auto bottom, or seal end design featuring a perforated area in the front panel for dispensing.

-

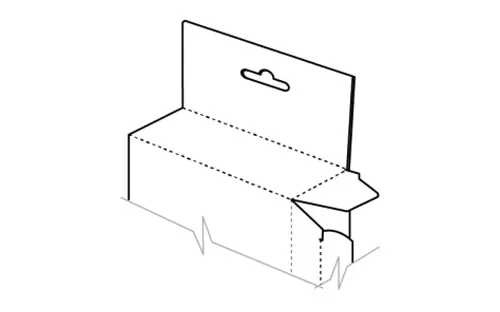

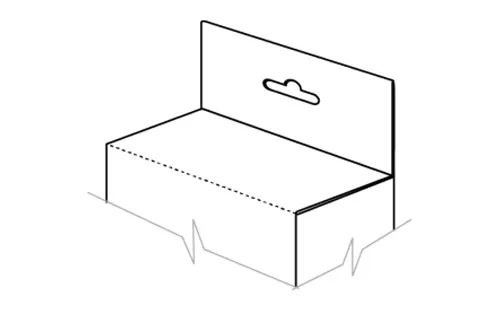

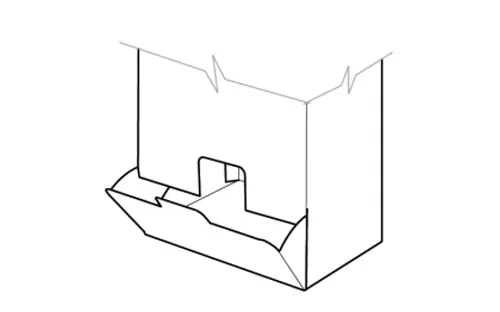

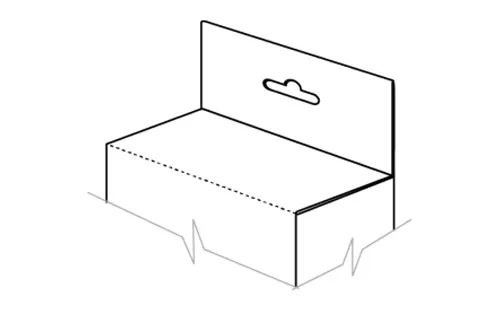

Tuck top or seal end design featuring an extra panel on the side of a box for hanging.

-

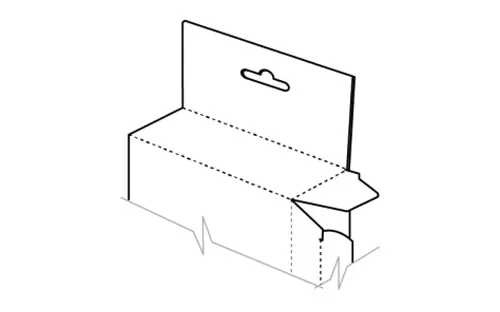

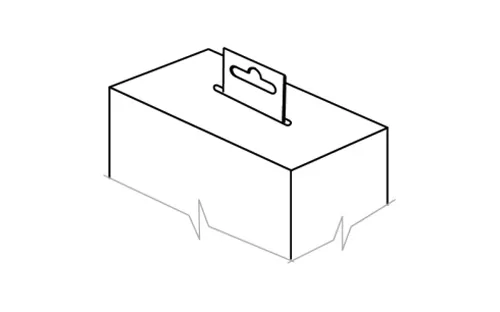

Tuck top or seal end design featuring an extra panel on the back of a box for hanging.

-

Tuck top or seal end design featuring a slit with a tab designed for hanging a box.

-

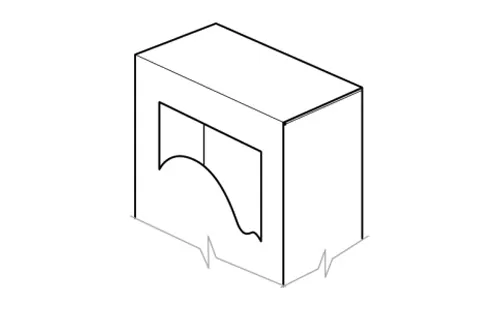

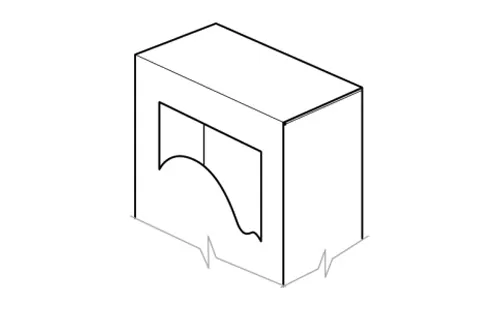

A shape is removed from the front of a box and covered with clear thin plastic to showcase products.

-

Tuck top design featuring a slit that locks with the panel to create a secure top.

-

Unique tuck top design featuring a long panel and a tab for secure sealing.

-

Tuck top design features two tabs and two slits for secure sealing and easy unboxing.

-

Added to tuck top designs, a notch is die-cut to create an easy and convenient unboxing experience.

-

Extended tab added to a variety of designs to add extra strength and support for sealing a box.

-

Tuck top and seal end design, interlocking flaps are added to help seal a box and block dust.

-

Flaps are added to block dust from entering the packaging with tuck top and seal end design.

-

Roll end design featuring tabs that slot between side panels to hold the top closed.

-

Tuck top design featuring a tab that is cut to create an edge for a convenient unboxing.

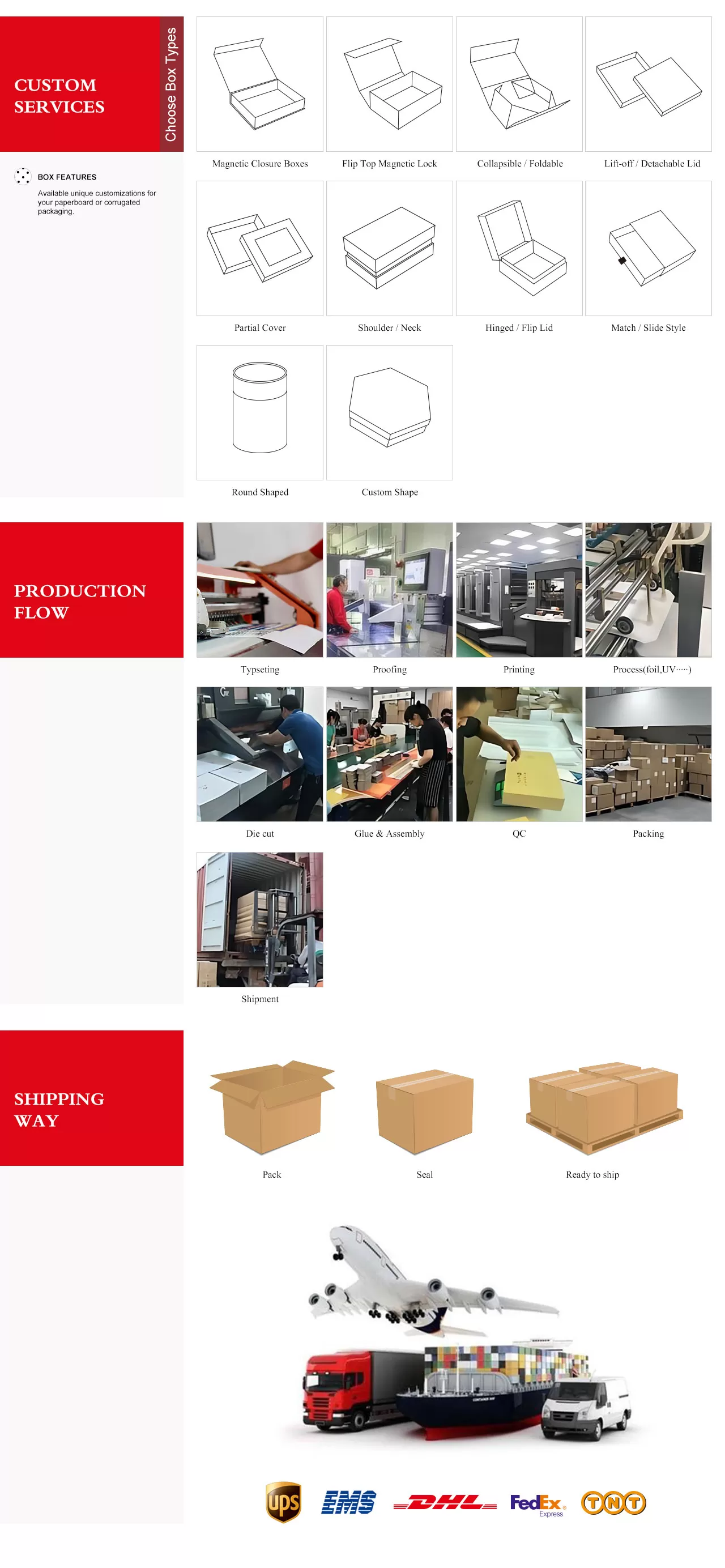

Our packaging experts design and engineer innovative structures tailored to your product and branding.Explore design & engineering

Our packaging experts design and engineer innovative structures tailored to your product and branding.Explore design & engineering Our packaging design specialists create exceptional custom artwork that showcase and bring your branding to the next level.Explore design & engineering

Our packaging design specialists create exceptional custom artwork that showcase and bring your branding to the next level.Explore design & engineering Create physical samples and 3D interactive prototypes final product packaging before making a final decision.Explore design & engineering

Create physical samples and 3D interactive prototypes final product packaging before making a final decision.Explore design & engineering